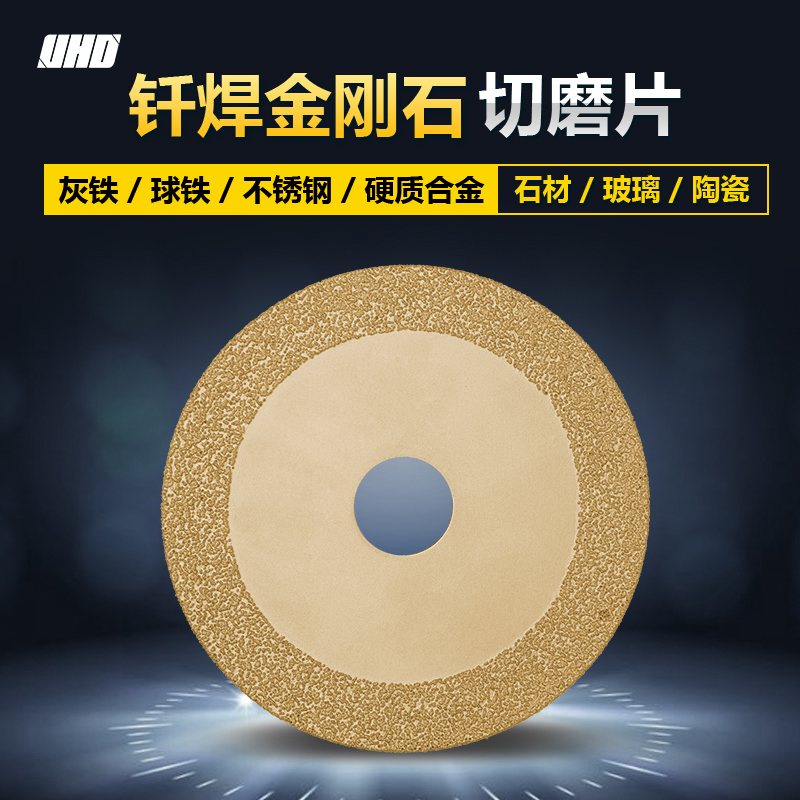

Henan Youde Superhard Tools Co., Ltd. has introduced a high - quality vacuum brazed diamond cutting grinding disc, which combines advanced vacuum brazing technology with diamond materials to create a new generation of cutting tools. This article will delve into the scientific principles and manufacturing processes of vacuum brazing technology, and highlight its impact on enhancing the performance of diamond cutting grinding discs.

Vacuum brazing is a precise and advanced manufacturing process. In a vacuum environment, a filler metal is heated to a molten state and then used to join the diamond segments to the tool base. This process eliminates the presence of oxygen and other impurities, preventing oxidation and ensuring a strong and reliable bond between the diamond and the base material. According to industry research, compared with traditional brazing methods, vacuum brazing can increase the bonding strength of the diamond segments by up to 30%, significantly improving the overall durability of the cutting tool.

The diamond cutting grinding discs from Henan Youde are designed with several remarkable features. Firstly, in terms of durability, the strong bond created by vacuum brazing allows the diamond segments to withstand high - intensity cutting operations. Tests have shown that these grinding discs can have a service life that is 2 - 3 times longer than traditional cutting tools. Secondly, in terms of safety, the stable structure of the tool reduces the risk of diamond segment detachment during operation. Finally, from an environmental perspective, the efficient cutting process generates less waste and dust, making it a more environmentally friendly choice.

In the foundry industry, the diamond cutting grinding discs from Henan Youde play a crucial role. For example, when removing burrs from cast iron and ductile iron, these tools can complete the task quickly and accurately. Traditional methods may take an average of 10 - 15 minutes to remove burrs from a single part, while the vacuum brazed diamond cutting grinding discs can reduce this time to 3 - 5 minutes, greatly improving work efficiency. Moreover, the longer service life of these tools means lower replacement frequencies, which in turn helps foundries reduce their operating costs.

As market demands continue to evolve and technology advances, vacuum brazing technology is leading the future development of metal cutting tools. The trend is towards more precise, durable, and environmentally friendly cutting solutions. Henan Youde's products are at the forefront of this trend, providing foundries and other industrial users with high - performance cutting tools that meet both current and future needs.

For foundries looking to improve their cutting efficiency and reduce costs, Henan Youde's vacuum brazed diamond cutting grinding discs are the ideal choice. With their long service life, high safety, and environmental friendliness, these tools offer a cost - effective solution for your cutting operations. Don't miss out on this opportunity to upgrade your cutting tools!