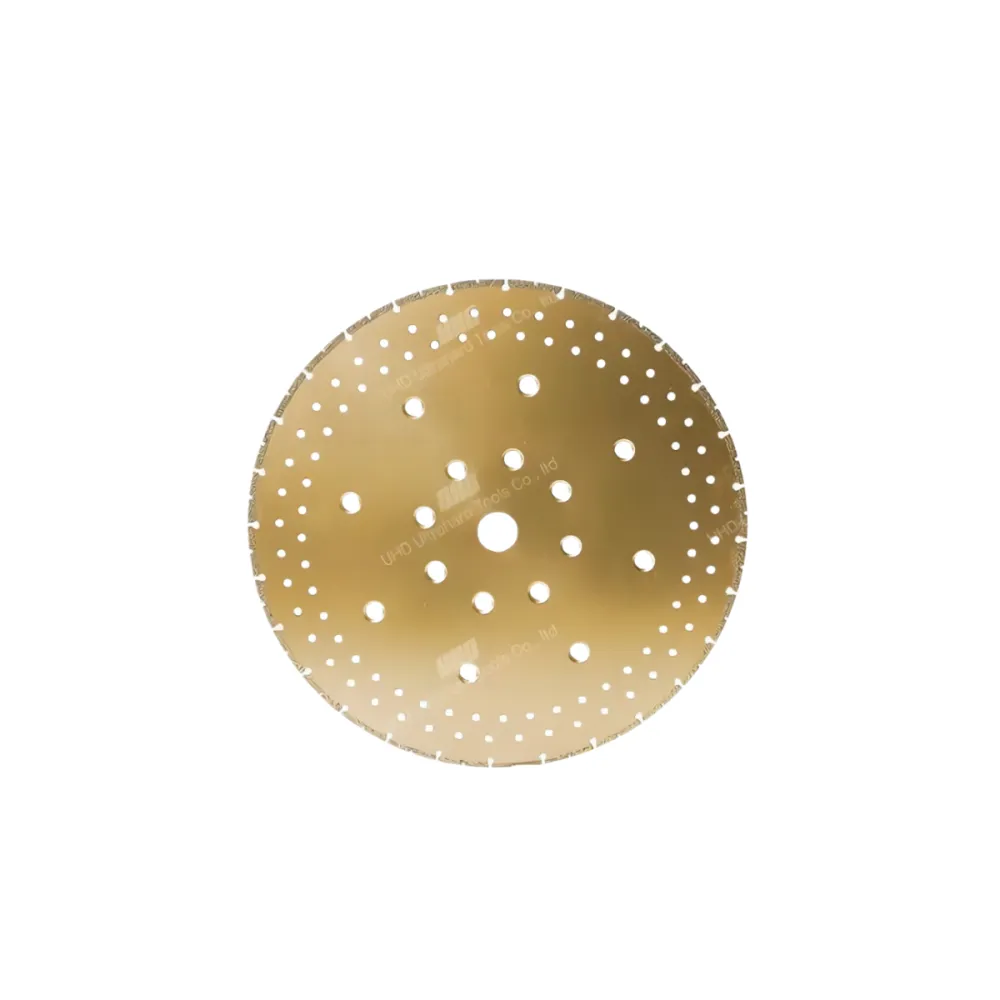

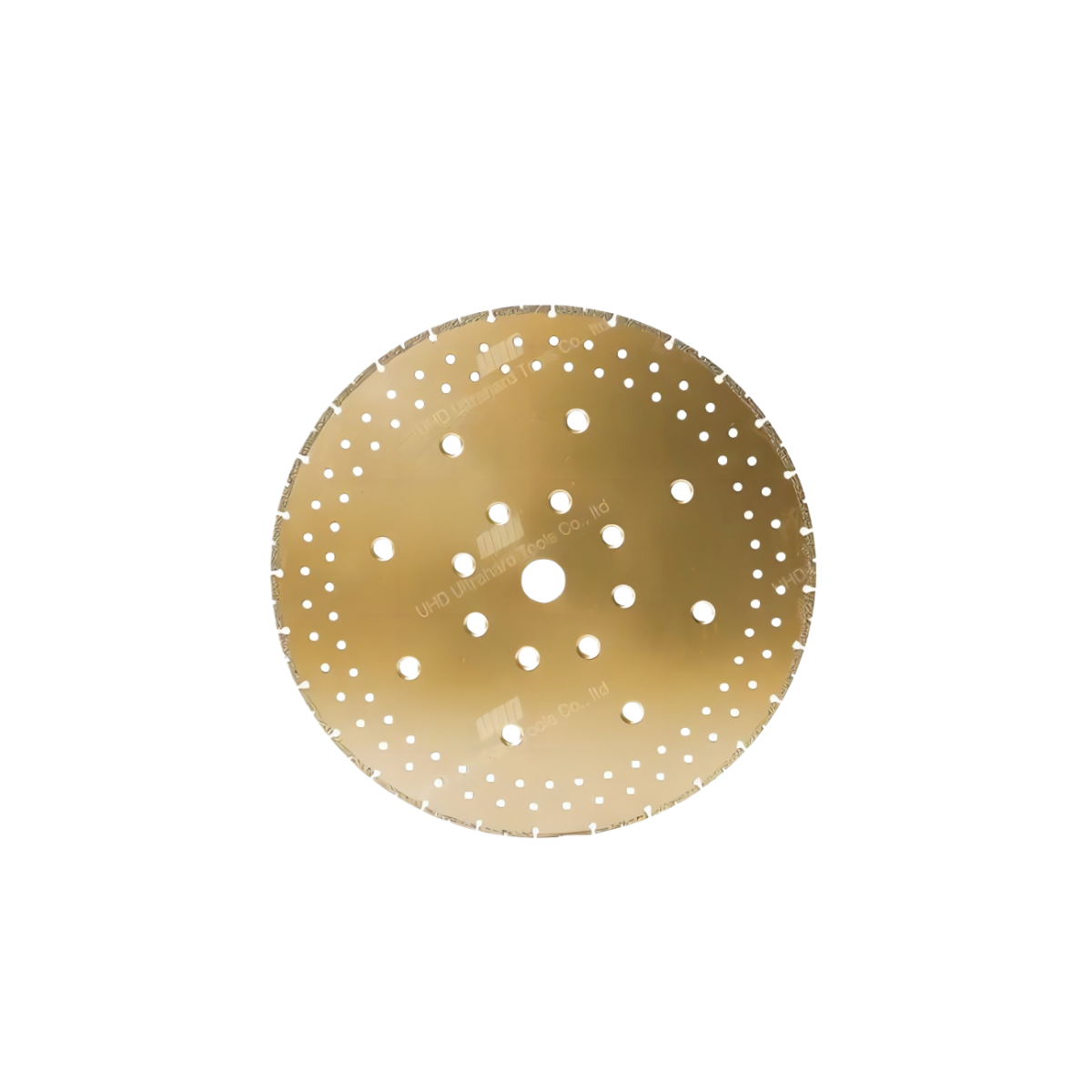

Vacuum brazed diamond grinding wheels represent a significant leap forward in abrasive technology, particularly for the demanding needs of the cast iron processing industry. Unlike traditional resin-bonded wheels, this advanced bonding technique delivers exceptional sharpness, prolonged tool life, and a virtually dust-free working environment — transforming productivity and safety standards.

At the heart of vacuum brazed diamond wheels lies the high-precision vacuum brazing process, where diamond abrasive grains are metallurgically bonded to the steel core under vacuum conditions, eliminating the need for organic binders. This enhances the wheel's grinding efficiency and heat dissipation capabilities.

Compared to traditional resin bonds, vacuum brazing provides 3 times the sharpness retention, enabling cleaner material removal with less frequent dressing cycles. Moreover, this process extends the lifespan by over 100 times, drastically reducing downtime and replacement costs.

The wheel's ultra-hard diamond surface excels in precise chip removal from challenging cast iron grades, including gray and ductile iron. The physicochemical bonding ensures consistent abrasive exposure, enabling swift and uniform burr elimination without deformation of the base material.

This efficiency is supported by experimental data indicating a 30-40% reduction in cycle time during deburring operations on automotive and industrial components, significantly accelerating workflows.

"Since adopting vacuum brazed diamond grinding wheels, our foundry noted a dramatic drop in particulate contamination and increased operator comfort—key factors in meeting strict environmental and safety regulations." – Industry Expert Feedback

One of the major barriers in abrasive machining is the generation of dust, which poses significant health hazards and complicates post-processing cleanup. Vacuum brazed diamond grinding wheels counter this challenge with a sealed structural design that minimizes abrasive debris escape.

Furthermore, their optimized high-speed rotation stability reduces vibration, securing uninterrupted and odorless operation. This results in a cleaner working environment and enhanced operator safety.

| Performance Indicator | Vacuum Brazed Wheel | Traditional Resin-Bonded Wheel |

|---|---|---|

| Tool Sharpness Retention | 3x longer | Baseline |

| Tool Lifespan | Up to 100x longer | Baseline |

| Energy Consumption | Reduced by 15% | Baseline |

| Machine Downtime | Reduced by 60% | Baseline |

Recognizing that different cast iron components demand specific grinding profiles, vacuum brazed diamond wheels are available in a range of custom geometric shapes. From flat wheels optimized for high-volume automotive parts to contoured wheels crafted for intricate mechanical assemblies, customization ensures optimal fit and maximum performance.

This adaptability empowers manufacturers to integrate dust-free grinding solutions seamlessly into varied production lines, enhancing flexibility without compromising quality.

The application of vacuum brazed diamond grinding wheels paves the way for a future where cast iron processing is both high-efficiency and environmentally responsible. The elimination of dust and odors, coupled with extended tool life and reduced energy demands, aligns perfectly with evolving regulatory standards and the shift towards Industry 4.0 smart factories.

Industries ranging from automotive component manufacturing to heavy machinery foundries have reported significant improvements in workplace safety and productivity, setting a new benchmark for sustainable manufacturing practices.