In the highly competitive metal cutting industry, finding the right technology and equipment is crucial for businesses aiming to enhance efficiency and reduce costs. Vacuum brazing technology has emerged as a game - changer, revolutionizing the way metal cutting is carried out. This article delves into the principles of vacuum brazing technology and its applications in the metal cutting field.

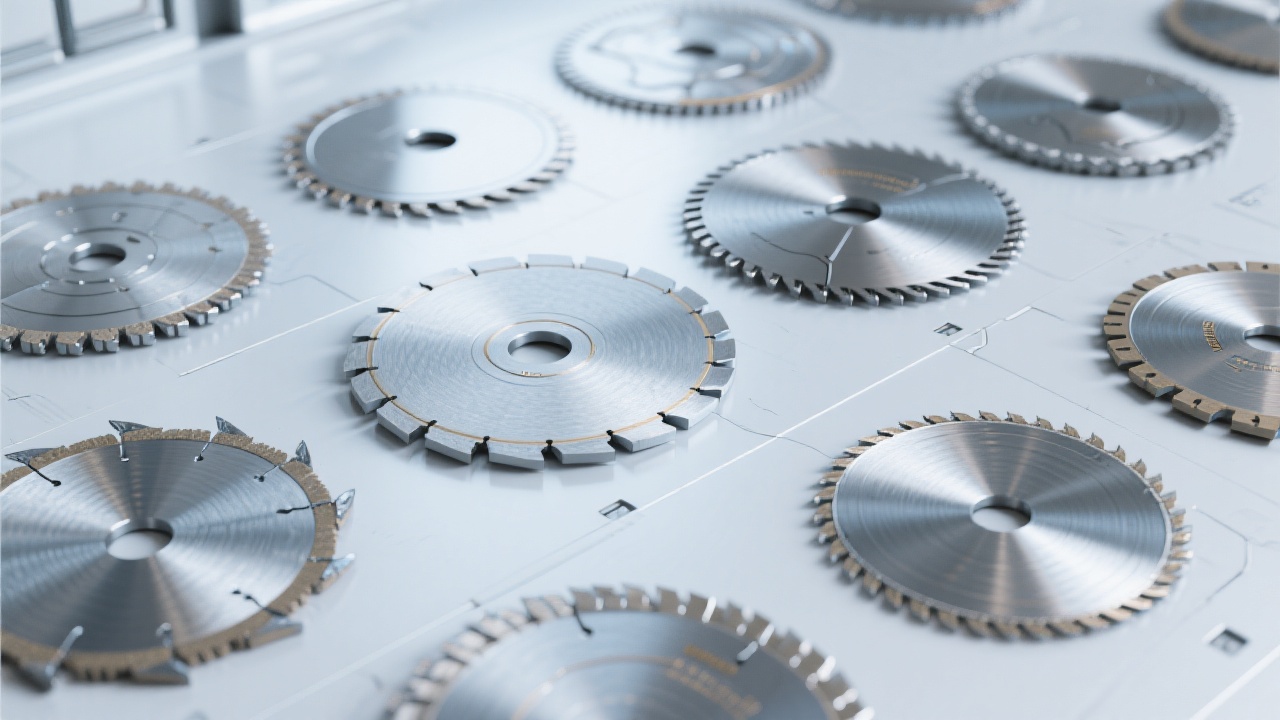

Vacuum brazing is a process that joins materials by heating them to a suitable temperature in a vacuum environment and using a filler metal. The absence of air in the vacuum prevents oxidation and contamination, ensuring a high - quality bond. In the metal cutting field, this technology is widely used to manufacture cutting tools such as high - performance diamond saw blades.

Compared with traditional metal cutting technologies, vacuum brazing equipment offers several significant advantages. Firstly, in terms of cutting efficiency, vacuum - brazed tools can achieve cutting speeds that are up to 30% faster. For example, in a case study of a metal processing factory, the use of vacuum - brazed saw blades reduced the time required for a specific cutting task from 60 minutes to 42 minutes.

Secondly, the tool life is greatly extended. Traditional cutting tools may need to be replaced after a few hours of use, while vacuum - brazed tools can last up to 5 times longer. This is due to the strong bond between the cutting edge and the tool body, which can withstand high - stress cutting operations without the cutting edge falling off easily.

In addition, vacuum brazing technology provides higher cutting precision. It can achieve a cutting tolerance of up to ±0.05mm, which is crucial for industries that require high - precision metal parts.

Henan Youde Superhard Tools Co., Ltd. is a prime example of a company that has successfully applied vacuum brazing technology. Their products have been well - received in the market due to their advanced technology and high - quality performance. The company's vacuum - brazed cutting tools have been used in various industries, including casting and emergency demolition.

In the casting industry, the company's tools can cut through thick and hard casting parts with ease, improving the overall production efficiency. In emergency demolition operations, the durability and high - speed cutting ability of their tools ensure that the operations can be completed quickly and safely.

Vacuum brazing technology can be customized to meet the specific needs of different industries. In the casting industry, where large - scale and high - precision cutting is required, the technology can be adjusted to produce tools with different blade shapes and cutting angles. In emergency demolition, where the tools need to be able to work in harsh environments, the vacuum - brazed tools can be designed to have high impact resistance and corrosion resistance.

The application of vacuum brazing technology has a positive impact on production efficiency and cost. By reducing the tool replacement frequency and increasing the cutting speed, companies can save up to 20% on production costs. Moreover, the high - precision cutting reduces the waste of raw materials, further optimizing the cost - benefit ratio.

In addition to the advanced technology itself, technical support and after - sales service are also crucial. Henan Youde Superhard Tools Co., Ltd. provides professional technical support to help customers install, operate, and maintain the equipment. Their after - sales service team is always ready to solve any problems that customers may encounter, ensuring a long - term and stable cooperation.

If you want to learn more about how vacuum brazing technology can transform your metal cutting operations, click here to explore further.