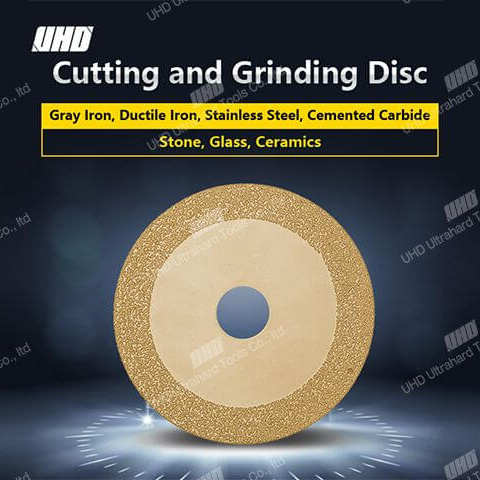

Vacuum brazed diamond grinding disks are a revolutionary tool in the field of metal processing. The basic principle behind these disks involves using high - temperature vacuum brazing technology to firmly bond diamond abrasives to the metal substrate. This process ensures a strong and stable connection between the diamond and the base, which is crucial for the performance of the grinding disk. The diamond abrasives, known for their extreme hardness, can effectively grind various metals with high precision.

One of the key technical features is the uniform distribution of diamond particles on the surface of the disk. This uniformity allows for consistent and efficient grinding, reducing the risk of uneven wear. Additionally, the advanced brazing technology enhances the heat - resistance of the disk, enabling it to withstand high - speed and high - pressure grinding operations without significant damage.

In the casting industry, dust pollution is a major concern. Vacuum brazed diamond grinding disks offer a solution with their dust - free grinding technology. Traditional grinding methods often generate a large amount of metal dust, which is not only harmful to the environment but also poses a health risk to workers. In contrast, these disks can achieve up to 90% dust reduction during the grinding process, according to industry research.

The efficiency of these disks is also remarkable. They can grind metals at a speed that is 30% faster than conventional grinding tools. This increased speed not only shortens the production cycle but also reduces energy consumption. From an environmental perspective, the combination of dust reduction and energy efficiency makes these disks an ideal choice for sustainable manufacturing.

Product safety is a top priority in the design of vacuum brazed diamond grinding disks. The structure of the disk is carefully engineered to prevent the diamond particles from falling off during operation. This reduces the risk of accidents caused by flying debris. Moreover, the disk's shape and size are designed to fit comfortably in the operator's hand, reducing fatigue and improving overall safety.

Durability is another outstanding feature. These disks can last up to 5 times longer than ordinary grinding disks. For example, in a real - world application at a large - scale casting factory, a vacuum brazed diamond grinding disk was able to grind over 1000 metal parts before showing significant wear, while a traditional disk could only handle about 200 parts under the same conditions.

Proper maintenance is essential for maximizing the lifespan of vacuum brazed diamond grinding disks. After each use, it is recommended to clean the disk with a soft brush to remove any metal debris. Regularly inspect the disk for signs of damage, such as cracks or loose diamond particles. If any issues are detected, immediate action should be taken to prevent further damage.

To prevent faults, it is important to use the disk within its specified parameters. Avoid overloading the disk or using it for inappropriate materials. By following these simple maintenance and prevention tips, the disk can maintain its optimal performance for a long time.

Henan Youde Superhard Tools Co., Ltd. understands that different customers have different needs. That's why they offer a wide range of vacuum brazed diamond grinding disks in various sizes, shapes, and diamond concentrations. Whether you need a small - sized disk for precision grinding or a large - sized one for heavy - duty operations, there is a suitable option available.

Moreover, the company also provides customization services. They can design and manufacture grinding disks according to the specific geometric requirements of customers. This flexibility allows customers to get the most out of the grinding disks for their unique applications.

Henan Youde Superhard Tools Co., Ltd. is committed to providing excellent technical support and services to its B2B customers. Their team of experts is always ready to offer advice on product selection, installation, and operation. They also provide after - sales services, including maintenance training and quick replacement of damaged parts.

With their high - quality products and reliable services, the company ensures that customers can achieve the best results in their metal processing operations.

Vacuum brazed diamond grinding disks have made significant contributions to the casting industry. They have improved production efficiency by reducing grinding time and increasing the speed of operations. At the same time, they have raised environmental standards by minimizing dust pollution and energy consumption.

If you are a B2B exporter in the casting or metal processing industry, don't miss out on the opportunity to enhance your production with these advanced grinding disks. Click here to learn more about Henan Youde Superhard Tools Co., Ltd.'s products and services and take your business to the next level.