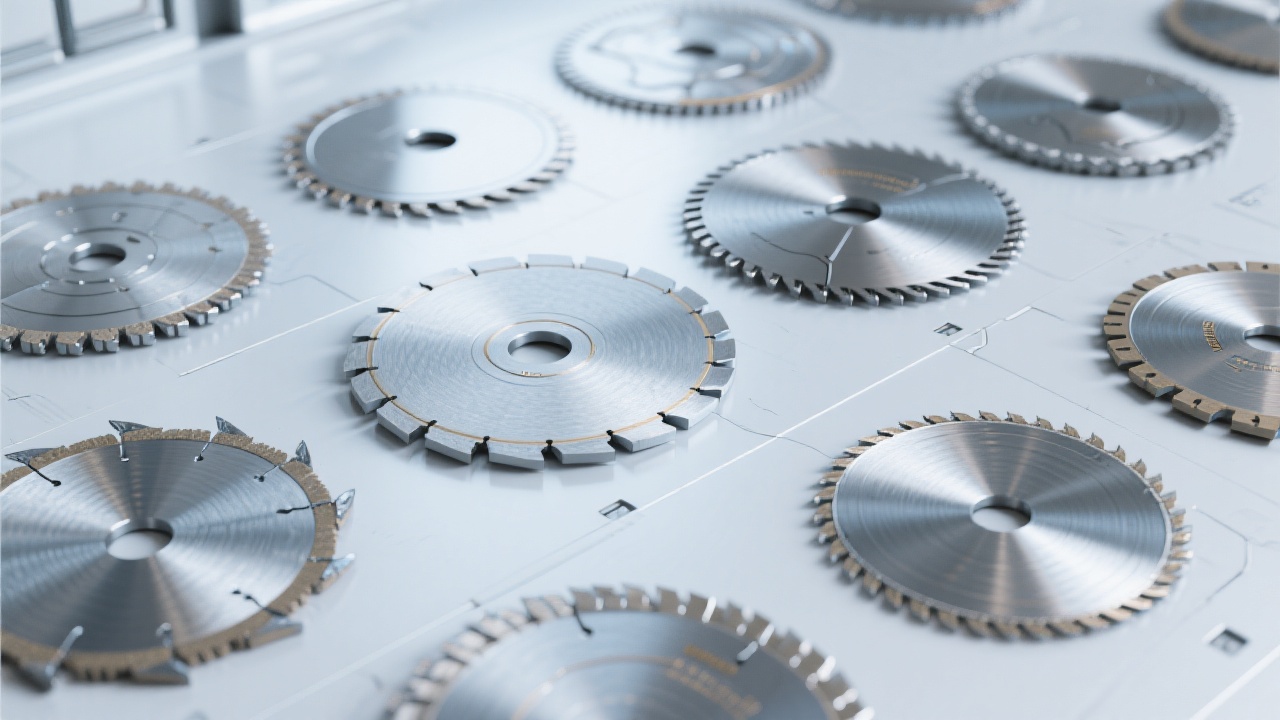

Henan Youde Superhard Tools Co., Ltd. stands out as a leading player in the field of customized diamond saw blades. With its profound expertise and advanced technologies, the company has been providing high - performance solutions to a wide range of industries.

The company's adoption of vacuum sintering technology is a game - changer in the diamond saw blade industry. This technology significantly enhances the performance of the saw blades in terms of cutting efficiency and lifespan. Studies have shown that saw blades manufactured using vacuum sintering technology can increase cutting efficiency by up to 30% compared to traditional methods. The vacuum environment during the sintering process eliminates impurities, resulting in a more uniform and dense blade structure. This not only improves the blade's cutting ability but also extends its service life. For example, in the casting industry, where cutting hard materials like grey cast iron and ductile iron is common, these saw blades can cut through large volumes of material with fewer blade changes, reducing downtime and increasing productivity.

One of the key strengths of Henan Youde is its ability to provide customized solutions for different cutting materials. Whether it's cutting granite, marble, or metals, the company can design and manufacture saw blades that are specifically tailored to the material's properties. The customization process starts with in - depth communication with the customer. The company's experts will understand the customer's cutting requirements, such as the type of material, cutting thickness, and cutting speed. Based on this information, they will select the appropriate diamond grade, bond type, and blade design. For urgent orders, Henan Youde has a streamlined production process that can deliver high - quality saw blades within a short time frame. For instance, a customer in the automotive industry needed a saw blade for a new production line with a tight deadline. Henan Youde worked closely with the customer, and within just 7 days, they provided a customized saw blade that met all the requirements.

| Cutting Material | Customization Focus | Expected Efficiency Improvement |

|---|---|---|

| Grey Cast Iron | High - strength bond, sharp diamond grit | 25 - 30% |

| Ductile Iron | Tough bond, wear - resistant diamond | 20 - 25% |

| Granite | Coarse diamond grit, optimized segment design | 15 - 20% |

.png)

To illustrate the effectiveness of its solutions, let's look at some real - world customer cases. A stone processing company was struggling with low - quality saw blades that frequently broke during cutting. After switching to Henan Youde's customized diamond saw blades, they experienced a 40% reduction in blade breakage and a significant improvement in the smoothness of the cut surface. Another customer in the metalworking industry reported a 25% increase in production output after using Henan Youde's saw blades, thanks to the blades' high cutting efficiency and long lifespan.

Henan Youde doesn't just stop at providing high - quality saw blades. The company also offers comprehensive technical support and after - sales service. Their team of experts is always available to answer customers' questions, provide on - site training, and offer maintenance advice. This ensures that customers can make the most of their saw blades and achieve the best cutting results.

Are you looking for a reliable partner to provide customized diamond saw blades for your cutting needs? Henan Youde Superhard Tools Co., Ltd. is the answer. With its advanced technology, customized solutions, and excellent service, the company can help you achieve efficient and precise cutting, and enhance your business competitiveness. Click here to learn more and get in touch with our experts!