In contemporary construction and stone fabrication, cutting tools must meet demanding requirements including versatility, durability, and safety. The UDS010 diamond blade emerges as a high-performance solution engineered to optimize cutting operations across varying material hardness and depths. This article presents an in-depth technical exploration of the UDS010, illustrating how its unique features contribute to enhanced productivity and cost-efficiency through real-world application cases.

Construction projects commonly face diverse cutting challenges, such as varied material hardness—from soft concrete to dense granite—and inconsistent cutting depths that require adaptable tooling. Additionally, fluctuating environmental conditions demand blades capable of both dry and wet cutting to maintain performance and safety. Users seek blades combining longevity, precision, and safety mechanisms, to reduce downtime and labor costs.

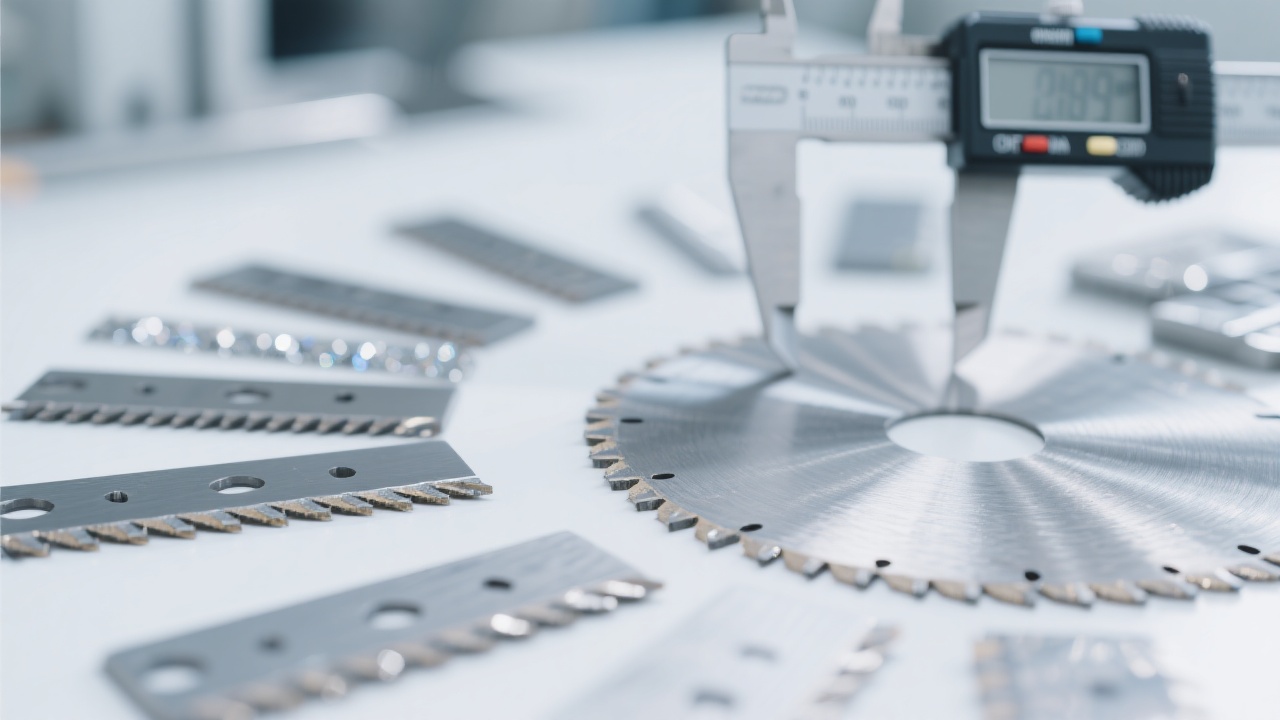

At the core of the UDS010's design is an optimized diamond grit concentration and bond matrix that ensures a precise balance between cutting speed and blade life. Compared to conventional blades, UDS010 delivers up to 15% faster cutting rates on reinforced concrete and maintains edge sharpness for 30% longer operational hours. Its multi-segment rim structure enhances cooling and debris ejection efficiency, preventing overheating and blade warping.

The blade diameter ranges from 300mm to 600mm, facilitating use on handheld grinders and large-scale saws, ensuring compatibility with varied jobsite equipment. The precision-engineered arbor hole tolerances guarantee stability and reduce vibration, contributing to cleaner cuts and lower operator fatigue.

The UDS010’s dry-wet dual capability represents a significant advancement. Dry cutting mode proves essential under site restrictions where water use is limited, maintaining cutting speed within 95% of wet performance while minimizing dust via its segmented rim design. In wet mode, continuous water flow dissipates heat effectively, extending blade lifespan and reducing microfractures in stone materials.

Independent third-party testing reveals that using UDS010 in wet mode improves blade life by approximately 40% compared to dry-only blades under identical conditions, highlighting the practical benefits of the dual-mode design for projects with varying site constraints.

Recognizing the diversity in cutting tasks, UDS010 offers a spectrum of blade diameters and thicknesses configurable to specific industry needs—ranging from architectural stone processing to heavy infrastructure projects. Custom fabrication options include specialized bonding agents and segment heights tailored for abrasive or ultra-hard stone varieties.

For instance, a recent project involving precision cutting of marble façade panels in Italy required a 350mm variant with a reinforced bond, resulting in a reduction of blade wear by 25% over previous tools, directly improving project turnaround times without compromising surface finish quality.

In a large-scale commercial building project in Dubai, UDS010 blades were deployed to cut various materials including basalt stone, engineered concrete, and granite slabs. Operators reported a consistent cutting speed of 0.8–1.2 meters per minute at depths up to 50mm, representing a 20% enhancement over the previously used standard blades.

Safety was reinforced via the blade’s reinforced core and integrated anti-vibration design, which substantially reduced operator fatigue and minimized the risk of blade fracture. The dry-wet versatility also shortened the preparation time between switching materials and site conditions.

Maintenance protocols established for UDS010 emphasize regular diamond segment inspections and cleaning, resulting in sustainable performance preservation—downtime was cut by 15% compared to historical averages on similar projects.

Effective maintenance is crucial for maximizing the service life of diamond blades. For UDS010 users, adherence to recommended inspection intervals—every 40 operational hours—is key. Cleaning debris and resin build-up with specialized blade cleaners maintains segment exposure and cutting efficacy.

Additionally, monitoring blade vibration and temperature during operations allows early detection of potential wear issues, preventing catastrophic failures. With proper care, clients have extended blade life cycles from average 150 hours to over 200 operational hours, reflecting in reduced procurement and operational costs.

| Feature | Benefit | Performance Metric |

|---|---|---|

| Optimized Diamond Grit & Bond | Faster cutting & longer blade life | 15% speed increase, 30% longer usage |

| Dry & Wet Cutting Compatibility | Flexible site application & dust reduction | 40% longer life in wet mode |

| Multi-size Range & Customization | Fulfills diverse project requirements | 25% wear reduction in specialized cuts |

Ready to elevate your cutting efficiency with UDS010? Discover tailored diamond blade solutions for your project today.