Vacuum brazing technology has emerged as a game - changer in the field of high - performance metal cutting. This advanced technique offers a range of benefits that significantly enhance the quality and efficiency of metal cutting processes. At its core, vacuum brazing is a method of joining materials using a filler metal that melts at a lower temperature than the base materials. The process takes place in a vacuum environment, which eliminates the presence of oxygen and other contaminants, resulting in stronger and more reliable joints.

One of the key advantages of vacuum brazing in metal cutting is its ability to improve the overall performance of cutting tools. By creating a strong bond between the cutting edge and the tool body, vacuum brazing enhances the tool's durability and resistance to wear. This leads to longer tool life and reduced replacement costs, making it an attractive option for businesses looking to optimize their cutting operations.

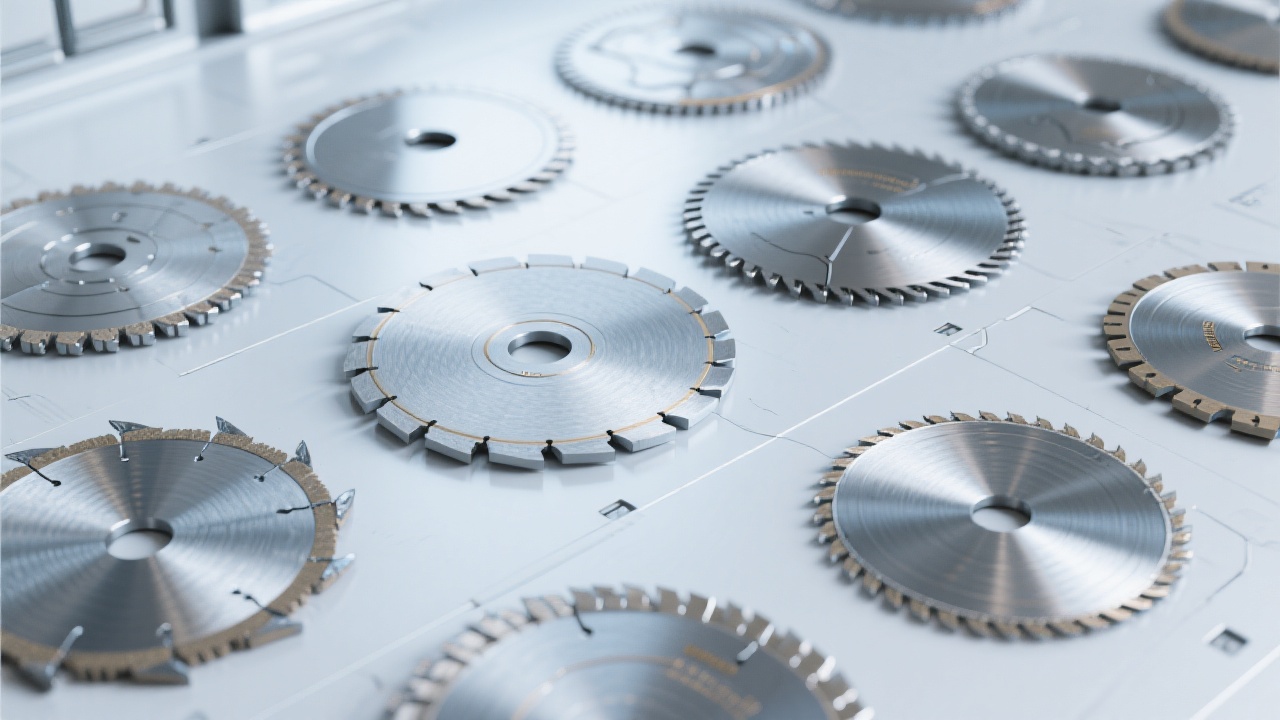

Henan Youde Superhard Tools Co., Ltd. has been at the forefront of applying vacuum brazing technology to its diamond saw blades. Through their unique vacuum sintering process, the company has been able to significantly enhance the performance of their products. For instance, the vacuum sintering technology used by Henan Youde can increase the saw blade's lifespan by up to 30% compared to traditional manufacturing methods. This is due to the strong bond formed between the diamond segments and the blade body, which reduces segment loss during cutting operations.

In addition to improved durability, the vacuum sintering process also enhances the cutting stability of the diamond saw blades. By ensuring a more uniform distribution of the filler metal, the saw blades can maintain a consistent cutting performance, resulting in smoother cuts and fewer vibrations. This not only improves the quality of the cut but also reduces operator fatigue and machine wear.

Vacuum brazing technology plays a crucial role in meeting the specific needs of the casting and emergency demolition industries. In the casting industry, the technology offers excellent material compatibility, allowing for the use of different types of base materials and filler metals. This enables the production of customized cutting tools that can effectively cut through various casting materials, such as steel, iron, and aluminum.

When it comes to emergency demolition, the high - performance cutting tools produced using vacuum brazing technology can quickly and efficiently cut through metal structures. The tools' ability to maintain their cutting performance under extreme conditions makes them ideal for emergency situations where time is of the essence. Moreover, the technology's high precision and speed ensure minimal damage to the surrounding structures, reducing the overall cost and time of the demolition process.

Vacuum brazing technology has a significant impact on cutting speed, precision, and cost - effectiveness. By improving the bond strength between the cutting edge and the tool body, the technology allows for higher cutting speeds without sacrificing tool life. This can lead to a 20% - 30% increase in cutting speed, depending on the application. Additionally, the precise control of the brazing process results in more accurate cuts, reducing the need for secondary finishing operations.

From a cost - effectiveness perspective, the longer tool life and higher cutting speeds achieved through vacuum brazing translate into lower operating costs. Businesses can reduce their tool replacement costs and increase their overall productivity, leading to a more competitive position in the market. A comparison table below shows the differences between traditional cutting tools and those using vacuum brazing technology:

| Performance Indicator | Traditional Cutting Tools | Tools using Vacuum Brazing Technology |

|---|---|---|

| Tool Life | 6 - 8 hours | 8 - 10 hours |

| Cutting Speed | 5 - 10 m/min | 6 - 13 m/min |

| Cutting Precision | ±0.5 mm | ±0.2 mm |

The future of vacuum brazing technology in the metal cutting industry looks promising. As the demand for high - performance cutting tools continues to grow, the technology is expected to become more advanced and widely adopted. New developments in materials science and process control will likely lead to even better - performing cutting tools with enhanced durability, cutting speed, and precision.

To stay competitive in the market, businesses like Henan Youde Superhard Tools Co., Ltd. need to continue investing in research and development. By leveraging the latest technological advancements, they can offer customized solutions that meet the evolving needs of their customers. The company's commitment to innovation and its ability to provide high - quality, technologically advanced products will enable it to maintain its position as a leader in the high - end cutting tool market.

Are you ready to take your metal cutting operations to the next level? Explore Henan Youde Superhard Tools Co., Ltd.'s innovative solutions and experience the benefits of vacuum brazing technology. Click here to learn more!