In today’s high-precision industrial pipeline manufacturing sector, tool wear and inconsistent surface finish remain critical bottlenecks—especially when working with ductile cast iron components that demand both strength and dimensional accuracy. According to a 2023 industry report by Manufacturing Engineering Magazine, over 68% of metalworking shops cite premature tool failure as a top contributor to production delays.

Conventional brazed or resin-bonded diamond wheels often fail under continuous heavy-load conditions. On average, they last only 3–5 hours before requiring reconditioning—a downtime cost estimated at $150–$300 per hour for high-value pipe sections (source: International Journal of Advanced Manufacturing Technology). This not only increases operational costs but also introduces variability in surface roughness, affecting downstream assembly processes.

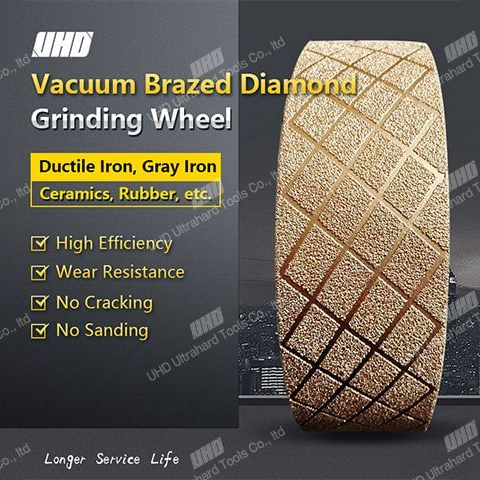

That’s where vacuum brazed diamond grinding wheels from Henan Yode Superhard Tools Co., Ltd. make a measurable difference. Engineered using advanced vacuum brazing technology, these wheels offer up to 3x longer lifespan compared to standard alternatives—reducing tool change frequency by 65% in real-world applications across oil & gas and power generation sectors.

The integration of multi-axis automatic grinding systems with vacuum brazed wheels enables consistent control over cutting parameters such as depth of cut, feed rate, and coolant flow. In tests conducted at a major Chinese pipe manufacturer, this combination achieved an average surface finish of Ra 0.4 μm—well within the tolerance range required for API 5L pipelines.

| Feature | Standard Wheel | Vacuum Brazed Diamond Wheel |

|---|---|---|

| Avg. Life (hours) | 3–5 | 10–15 |

| Surface Finish (Ra, μm) | 1.2–2.0 | 0.4–0.7 |

| Tool Change Time Reduction | N/A | Up to 65% |

Every industrial pipe profile has unique requirements—from wall thickness variation to alloy composition. Yode’s ultra-high-definition series offers customizable grit sizes (from 80 to 300 mesh), bond types, and wheel geometries tailored to specific machining challenges. One European client reported a 22% improvement in throughput after adopting a custom-designed wheel for thin-wall stainless steel pipes—an outcome directly tied to optimized heat dissipation and reduced chatter during grinding.

These innovations aren’t just theoretical—they’re backed by field validation across more than 150 global clients in energy, automotive, and infrastructure industries. Whether you're scaling up production or seeking precision consistency, the vacuum brazed diamond solution provides a clear ROI through reduced labor, lower scrap rates, and fewer quality reworks.

If your team is facing recurring tool wear issues or struggling to meet tight tolerances in pipe machining, now is the time to explore what modern grinding technology can do for your operation.