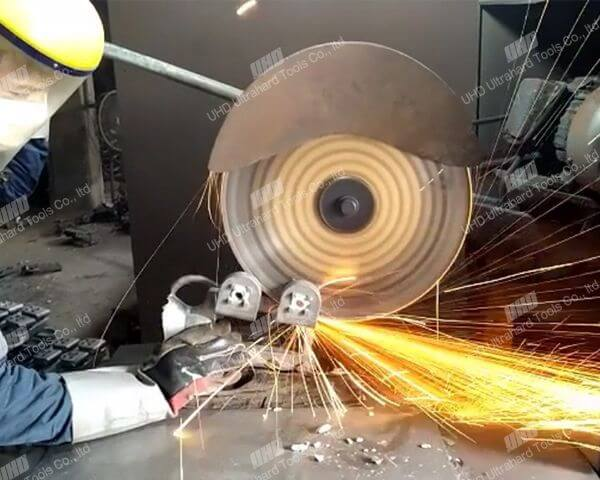

In today's fast-evolving industrial landscape, selecting the right high-speed cutting tools is paramount to optimizing performance and cost-efficiency. This analysis delves into the vacuum brazed diamond saw blades applied in high-powered cutting equipment, focusing on how varying speed ranges affect their operational efficiency and lifespan. Specifically, we compare two UHD Superhard Tools' flagship models — the UDS 600M16 and UDS 400amp 80 — to provide actionable recommendations for mechanical engineers, equipment operators, and procurement specialists aiming to maximize production throughput while maintaining safety and tool longevity.

Vacuum brazed diamond saw blades rely heavily on the synergy between blade geometry and material composition to sustain performance at elevated cutting speeds. The UDS 600M16 is engineered for ultra-high-speed applications exceeding 600 meters per second (m/s), leveraging an optimized diamond grit distribution and reinforced vacuum brazing for enhanced bonding strength. In contrast, the UDS 400amp 80 targets mid-speed operations around 400 m/s, balancing cutting stability with cost-effective wear rates.

| Model | Optimal Speed Range (m/s) | Diamond Grit Size (μm) | Bonding Strength (MPa) | Average Lifespan (hours) |

|---|---|---|---|---|

| UDS 600M16 | 550 - 670 | 16 | 85 | 120 - 150 |

| UDS 400amp 80 | 350 - 450 | 80 | 75 | 100 - 130 |

As illustrated, the UDS 600M16’s finer grit enables superior cutting precision suitable for materials requiring minimal kerf widths while its bonding strength accommodates faster spindle rotations. Conversely, the coarser 80-micron grit of the UDS 400amp 80 offers robust material removal rates, ideal for less delicate applications or where blade wear replacement cycles must be balanced with cost constraints.

The geometric profile of the blade edge significantly influences cutting efficiency and thermal dissipation during high-speed operations. The UDS 600M16 integrates a multi-faceted bevel design tailored for reducing cutting resistance on hard composites such as silicon carbide and ceramics. Meanwhile, the UDS 400amp 80 employs a uniform diamond layer optimized for metal and stone cutting where toughness outweighs fine edge precision.

Industrial clients engaging with multiple material types benefit from understanding this differentiation to avoid premature blade degradation and unsafe cutting conditions caused by thermal overload or mechanical chipping.

Proper installation and regular maintenance extend the operational life of vacuum brazed diamond saw blades substantially. For both UHD models, it is critical to ensure spindle runout is maintained under 0.02mm to prevent uneven wear. Lubrication channels on blade hubs must be free from debris to facilitate heat dissipation. Scheduled ultrasonic cleaning every 100 operating hours prevents diamond grain clogging and maintains cutting clarity.

| Maintenance Step | Frequency | Expected Outcome |

|---|---|---|

| Blade Runout Measurement | Before Each Shift | Minimize vibration-related wear |

| Ultrasonic Cleaning | Every 100 Hours | Ensure diamond grain exposure and cutting efficiency |

| Lubrication Check | Weekly | Prevent overheating and blade warping |

Challenges such as blade chipping, reduced cut quality, and overheating are frequent pain points in industrial applications. UHD’s UDS 600M16 manifests superior resistance to microchipping due to its high bonding strength, making it suitable for high-torque applications like aerospace component manufacturing. On the other hand, UDS 400amp 80 performs reliably in environments where moderate speeds prevail but requires more frequent inspections for thermal crack development.

These insights empower procurement teams to balance upfront investment against lifecycle costs effectively. Selecting an optimal blade according to machine specifications and material properties reduces downtime and enhances overall operational return on investment (ROI).

UHD Superhard Tools’ UDS series embodies best-in-class performance, combining durability with cost-efficiency. Procurement professionals should assess the following when making purchase decisions:

Implementing these strategies can significantly lower operational risks, improve throughput, and enhance product quality across high-speed cutting operations globally.