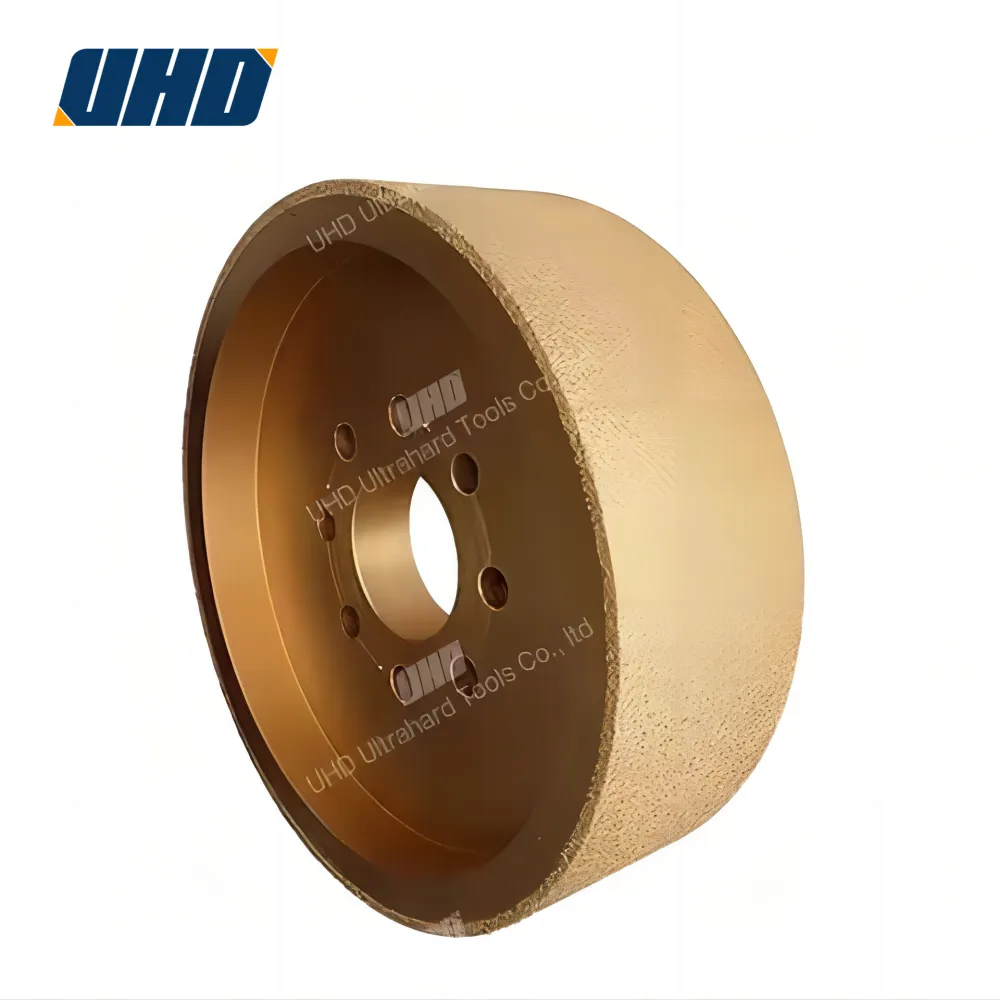

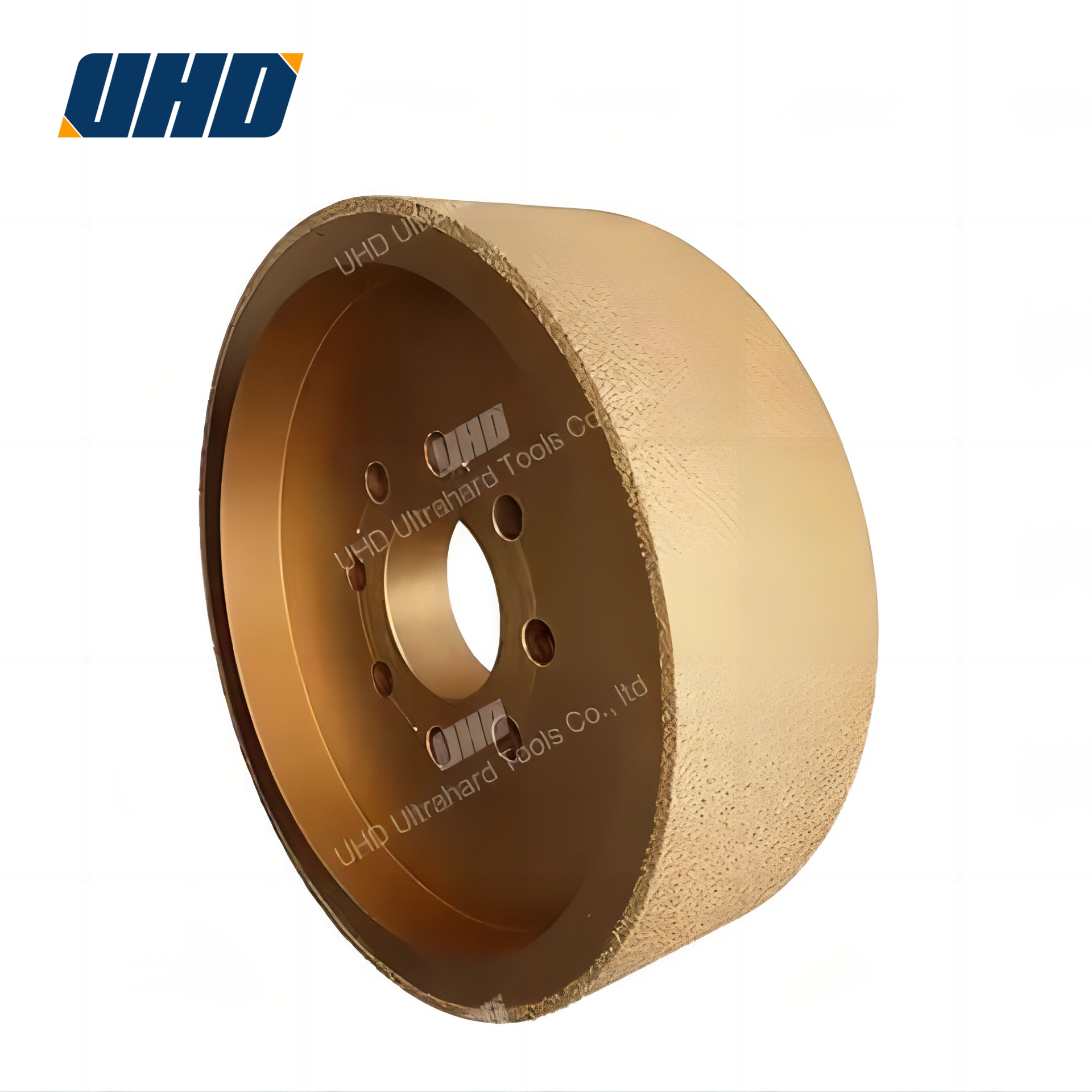

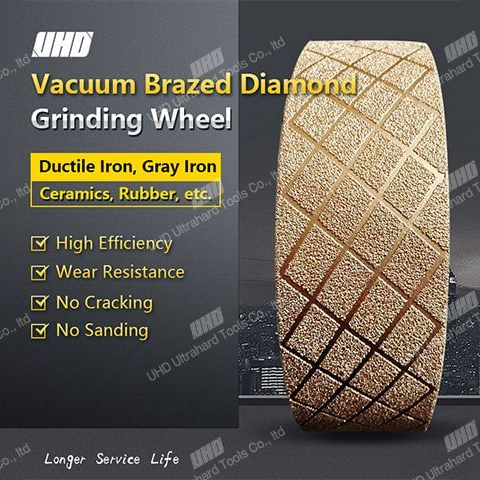

Henan Youde Superhard Tools Co., Ltd. has introduced a series of high - performance vacuum brazed diamond grinding wheels. These wheels are specifically designed for multi - axis automatic grinding equipment, which can significantly improve grinding efficiency and service life. The company, with years of experience in the superhard tool industry, has established a solid reputation for its commitment to quality and innovation.

The vacuum brazing technology used in Youde's diamond grinding wheels offers several distinct advantages. First, it provides a strong bond between the diamond grits and the wheel substrate. This bond allows the diamond grits to protrude higher from the wheel surface, increasing the cutting ability and reducing the probability of grit pull - out. As a result, the grinding efficiency can be improved by up to 30% compared to traditional grinding wheels, and the service life can be extended by 2 - 3 times.

Structurally, the unique design of the vacuum brazed diamond grinding wheels ensures better heat dissipation during the grinding process. This is crucial for high - speed and high - precision grinding operations, as it helps to maintain the dimensional stability of the workpiece and reduces the risk of thermal damage.

Youde offers a range of models, including UDW455, UDW405, UDW355, UDW305, and UDW255, each tailored to specific processing requirements:

| Model | Applicable Processing Scenarios | Optimized Parameters |

|---|---|---|

| UDW455 | Large - scale automotive parts grinding, such as engine blocks | High - speed rotation, large - diameter grinding, suitable for high - material - removal rate operations |

| UDW405 | Medium - sized automotive parts, like transmission gears | Balanced between speed and precision, optimized for medium - load grinding |

| UDW355 | Small - to - medium - sized parts with complex shapes | High - precision grinding, with fine - tuned parameters for smooth surface finish |

| UDW305 | Precision grinding of small automotive components | Low - vibration operation, ensuring high - accuracy dimensional control |

| UDW255 | Micro - parts grinding, such as fuel injectors | Ultra - fine grits, suitable for micro - machining and high - gloss surface finishing |

In the automotive parts manufacturing industry, precision and efficiency are of utmost importance. Youde's high - performance diamond grinding wheels have been widely used in this field. For example, in the production of engine cylinder heads, the UDW455 model can achieve a surface roughness of Ra 0.4 - 0.8μm, which meets the high - precision requirements of the automotive industry. Moreover, the long service life of the wheels reduces the frequency of wheel replacement, resulting in significant cost savings for manufacturers.

Youde's diamond grinding wheels are certified by ISO 9001:2015, which ensures strict quality control throughout the production process. The company also offers customized services to meet the specific needs of different customers. Whether it is a special size, shape, or performance requirement, Youde's professional R & D team can develop a tailored solution.

If you are looking to enhance your metal processing efficiency and precision, Youde's high - performance diamond grinding wheels are the ideal choice. With their advanced technology, wide range of models, and excellent quality, they can help you gain a competitive edge in the market. Don't miss this opportunity to upgrade your manufacturing process. Contact us now to get a professional solution tailored to your needs!