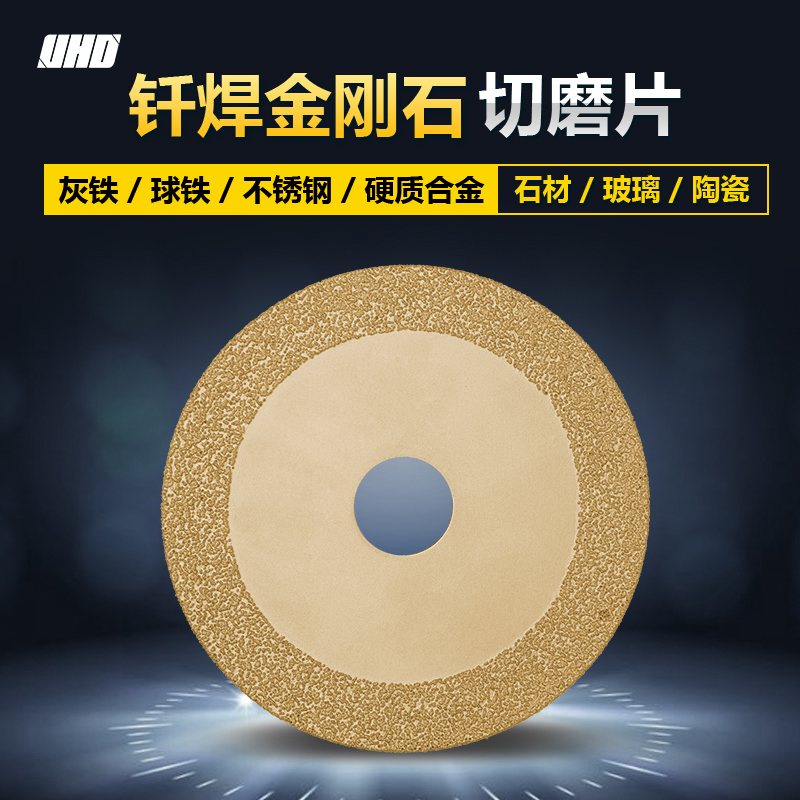

In an era where industrial precision and operational efficiency dictate competitiveness, vacuum brazed diamond cutting grinding wheels emerge as a transformative solution for the metalworking industry. Developed by Henan Yode Superhard Tools Co., Ltd, these state-of-the-art grinding wheels offer an unparalleled lifespan and safety profile, radically enhancing process outcomes in foundries and machining workshops.

Conventional resin-bonded grinding tools have long faced critical challenges including rapid wear, excessive dust generation, and inconsistent cutting sharpness. These pain points contribute to frequent tool replacements, deteriorated surface finishes, and compromised worker safety. Furthermore, the resin adhesives’ thermal and chemical vulnerabilities limit their application in demanding foundry environments involving cast irons.

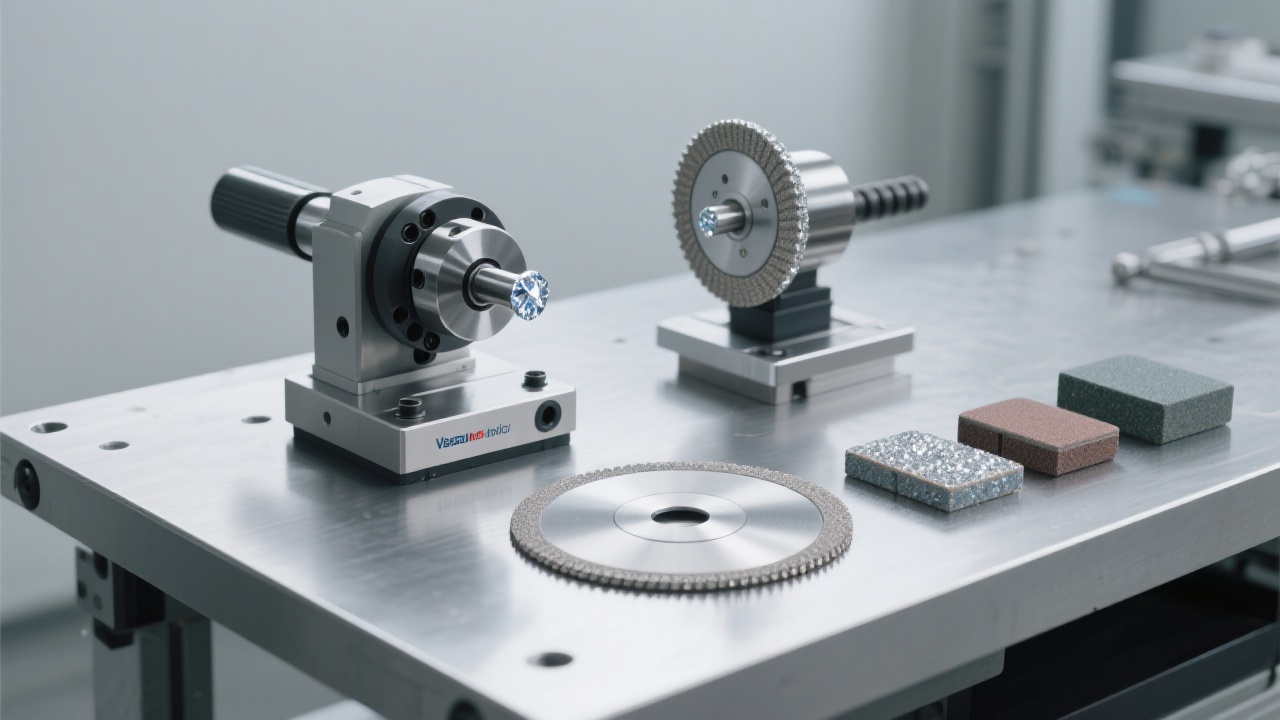

The core innovation underpinning these grinding wheels lies in advanced vacuum brazing technology, which tightly bonds diamond particles to a metallic substrate under vacuum conditions. This process achieves superior mechanical interlocking and chemical adhesion, resulting in a high-strength diamond layer with exceptional wear resistance and sharpness persistence.

Unlike resin bonds, vacuum brazing produces a virtually dust-free surface during grinding, as the diamond particles remain firmly fixed, minimizing micro-fracture debris emissions. This also eliminates the emission of toxic odors associated with resin breakdown, addressing stringent ESG (Environmental, Social, Governance) compliance requirements.

| Performance Indicator | Vacuum Brazed Diamond Wheel | Traditional Resin-Bonded Wheel |

|---|---|---|

| Tool Lifespan | Up to 100 times longer | Standard operational duration |

| Sharpness Retention | Sustained high-cutting efficiency | Rapid bluntness post-installation |

| Dust & Debris Emission | Near-zero dust generation | High dust exposure risks |

| ESG Compliance | Meets modern environmental standards | Limited compliance |

This vacuum brazed diamond grinding wheel shows excellent compatibility with challenging cast iron varieties such as ductile iron (nodular cast iron) and gray cast iron. Foundries requiring precise burr removal and surface refinement benefit from the tool’s high cutting consistency and stable finish quality.

Its geometric design adjusts seamlessly to diverse machining setups, offering remarkable adaptability in both manual and CNC grinding processes. This flexibility significantly reduces setup times and machining cycle durations, promoting overall throughput optimization.

The elimination of resin materials in bonding not only prevents hazardous fume release but also drastically reduces particulate pollution onsite. This upgrade aligns well with growing industrial commitments to worker safety, environmental stewardship, and regulatory compliance.

Factories deploying these grinding wheels report a noticeable reduction in respiratory complaints and maintenance downtime related to dust extraction systems—translating into enhanced operational continuity.

Available in a range of diameters (50mm to 300mm) and grain sizes, these grinding wheels can be custom-engineered for specific metalwork requirements. Feedback from industry leaders highlights remarkable improvements in surface finish quality and an unprecedented workload capacity per tool.

Typical applications span from deburring precision components to preparing surfaces for metallurgical testing, underscoring the tool’s versatility and reliability.

Integrating vacuum brazed diamond cutting grinding wheels into your production line marks a decisive stride toward increased machining precision, lower operational costs, and safer workplace environments.