Vacuum Brazed Diamond Grinding Wheels for Automated Metal Grinding: Core Technology and Performance Advantages

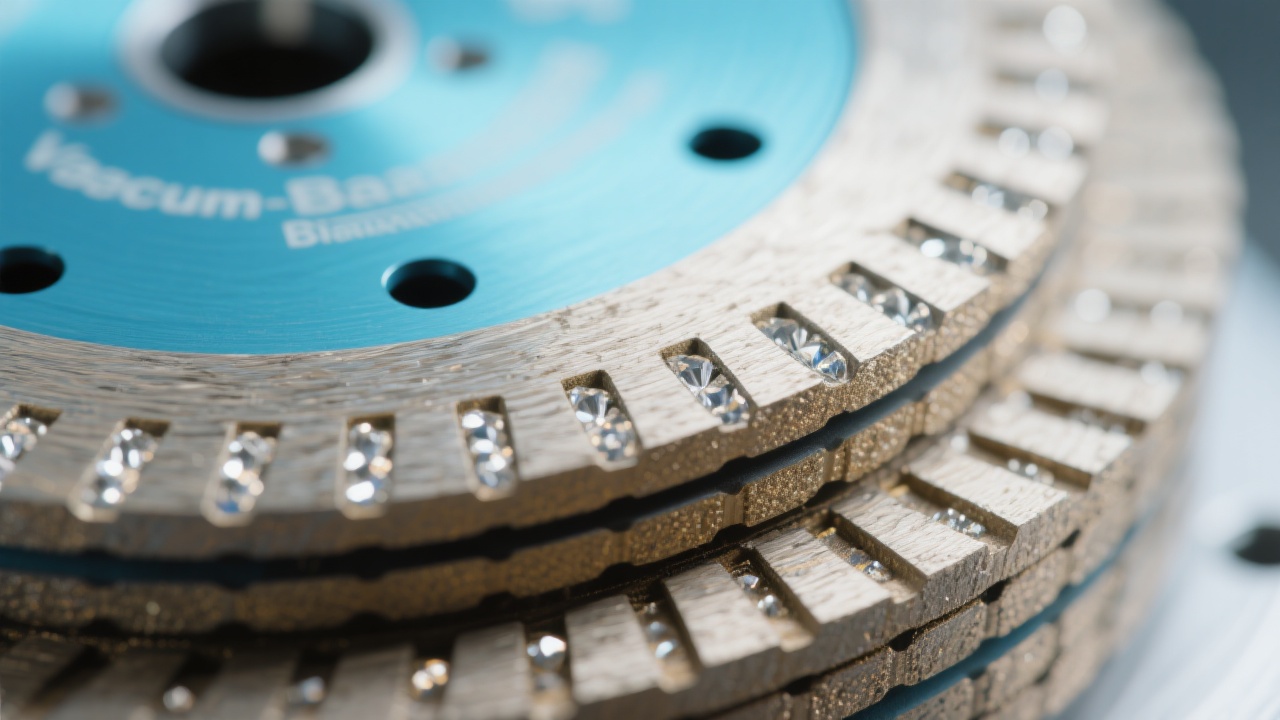

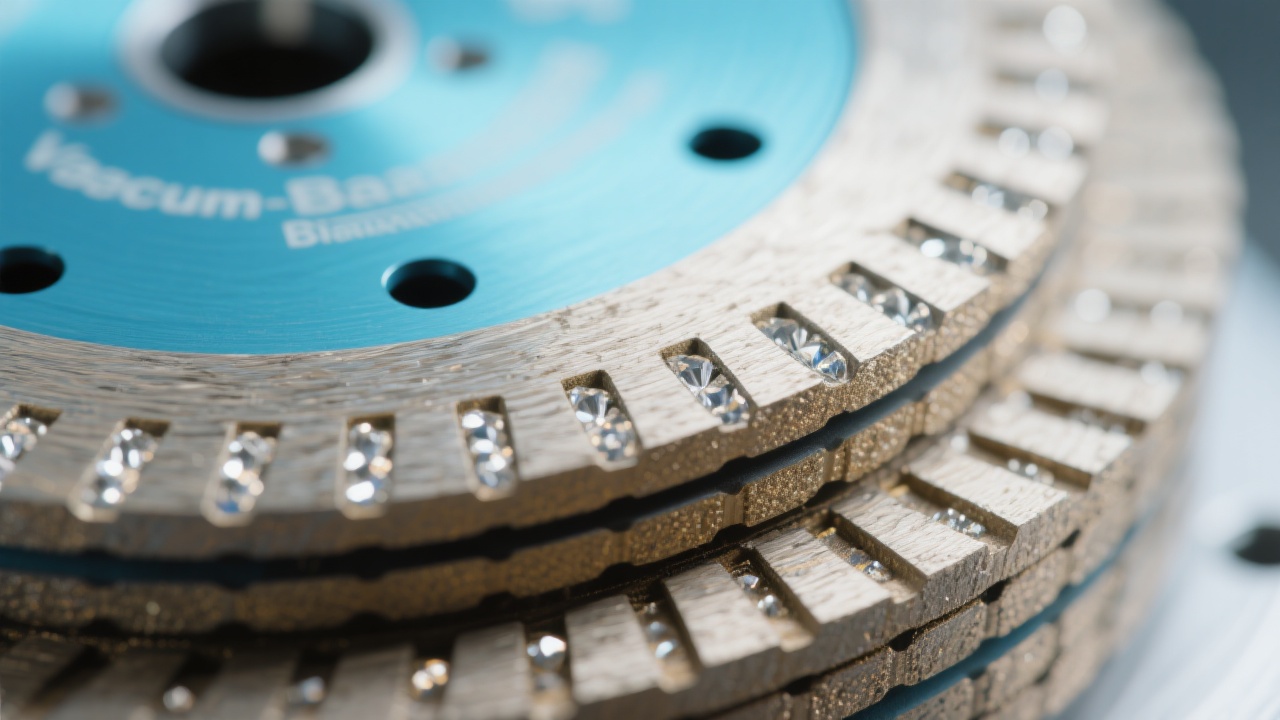

Vacuum brazed diamond grinding wheels are redefining automated metal grinding by combining a high-strength brazed bond with precise diamond exposure for stable, high-efficiency cutting. Compared with conventional electroplated wheels, vacuum brazing delivers stronger grit retention and a more open cutting structure, helping reduce dressing frequency, improve process consistency, and support high-precision finishing on demanding materials such as cast iron. In automated and multi-axis setups, UDW series wheels are engineered to maintain sharpness under continuous operation, typically enabling up to 30–60% longer service life and 20–40% higher material removal efficiency (results vary by application). This article highlights the key process innovations behind ultra-high-definition brazing, outlines application-driven design logic across UDW sizes, and explains how quality certification, inspection equipment, and customization services translate into lower total cost and more sustainable production. Readers will also find practical suggestions for comparison charts and an FAQ section to help evaluate performance—experience the difference and contact us to get a tailored solution for your line.

Vacuum Brazed Diamond Grinding Wheels for Automated Grinding: Core Technology and Why Manufacturers Are Switching

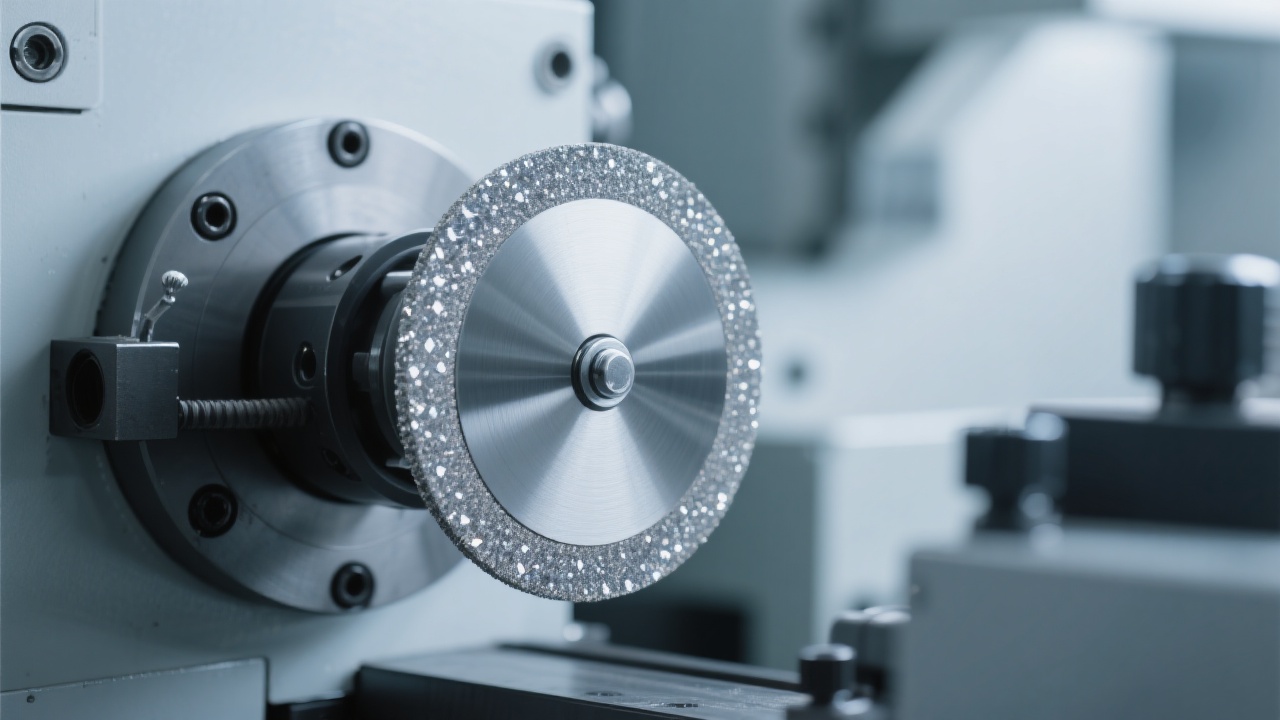

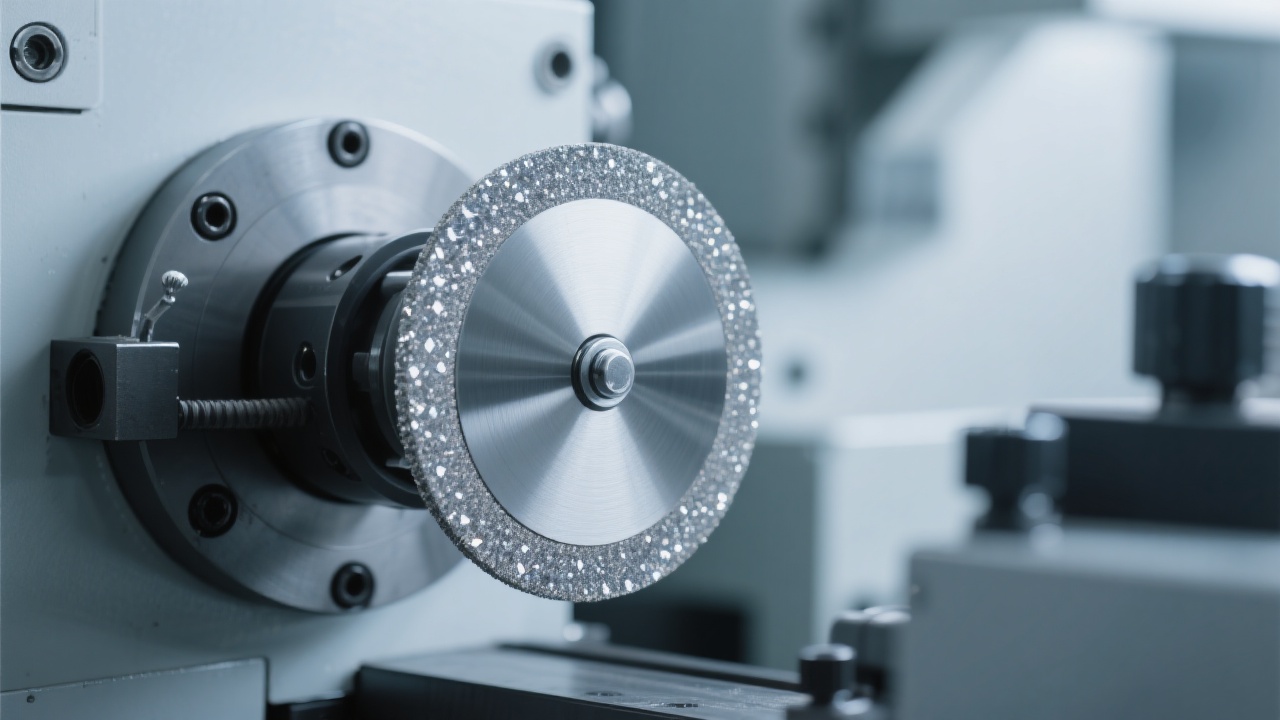

In automated metalworking, grinding wheels are no longer “consumables” in the traditional sense—they directly define cycle time, dimensional stability, tool life, and even the sustainability profile of a production line. Vacuum brazed diamond grinding wheels (often referred to as vacuum brazed superabrasive wheels) have become a serious contender to replace electroplated diamond wheels in high-demand applications such as cast iron processing and multi-axis automated equipment.

The UDW series vacuum brazed diamond wheels are positioned for automated grinding environments where predictable performance matters: higher material removal rates, longer usable life, and cleaner, more controllable wear behavior—without trading off precision.

SEO focus terms: vacuum brazed diamond grinding wheel, automated grinding wheel, superabrasive wheel advantages, high-efficiency metal grinding solution, custom diamond wheel service

1) Why Vacuum Brazing Is a Step-Change in Diamond Wheel Manufacturing

Vacuum brazing is not just another bonding method; it changes how abrasive grains are anchored and how the wheel behaves under load. In a controlled vacuum environment, a brazing alloy forms a metallurgical bond between the diamond grit and the wheel body. Compared with surface-level deposition, a brazed structure typically achieves deeper grain encapsulation and stronger retention, which is critical when automated grinding applies consistent pressure for long, uninterrupted runs.

In practical production terms, stronger grit holding means the wheel stays sharp longer, maintains cutting edges more consistently, and is less prone to premature grain pull-out—one of the main causes of unstable surface finish and sudden efficiency drops in automated cells.

Reference performance ranges (industry typical)

Depending on material, machine rigidity, and coolant strategy, vacuum brazed diamond wheels in automated grinding are commonly reported to deliver:

- ~20–40% higher material removal rate (MRR) versus electroplated wheels in comparable grit sizes

- ~30–80% longer effective service life (until performance becomes unstable for tolerance requirements)

- ~10–25% lower energy per part due to reduced rubbing and steadier cutting action

Note: Actual results depend on dressing strategy (if any), feed/speed, part geometry, and coolant delivery. These figures are presented as reasonable benchmarking references.

2) Vacuum Brazed vs. Electroplated: What Changes on the Shop Floor

Many buyers understand the basic difference—brazing versus plating—but what matters is how that difference shows up as measurable production outcomes. Automated grinding lines care about repeatability and predictable tool behavior. When a wheel’s cutting ability drops abruptly, the line pays twice: scrap risk rises and throughput falls.

Comparison table: technology differences that impact automated grinding

| Item |

Vacuum Brazed Diamond Wheel |

Electroplated Diamond Wheel |

| Grit retention |

Metallurgical bond; stronger anchoring under sustained loads |

Plated layer holds grains; may suffer earlier pull-out in heavy duty cycles |

| Wear behavior |

More stable cutting action; tends to keep “bite” longer |

Can drop in sharpness faster once top grains are lost |

| Process stability in automation |

Better consistency for multi-hour runs and robotic cells |

More sensitive to parameter shifts; may need closer monitoring |

| Typical use case |

High-efficiency metal grinding, automated lines, heavy stock removal |

Light-to-medium duty, simpler lines, cost-driven replacement cycles |

For decision-makers, the most important shift is not a lab metric—it’s the ability to hold a stable process window. Vacuum brazed wheels tend to provide a wider “safe zone” for feeds and speeds before the process becomes dominated by rubbing or thermal issues, which is exactly what automated grinding programs need.

3) Real-World Fit: Cast Iron Grinding and Multi-Axis Automation

Cast iron is widely used in automotive, pumps, valves, machine bases, and industrial housings. It is machinable, but it can be punishing in grinding due to abrasive inclusions, dust generation, and the need to balance stock removal with edge integrity. In automated cells, the challenge becomes even more visible: the wheel must cut efficiently without unpredictable degradation that disrupts part-to-part repeatability.

What automated lines typically want (and why vacuum brazing helps)

- Consistent grinding force to protect spindle bearings and maintain robotic path accuracy

- Predictable wheel life to schedule tool changes and avoid unplanned downtime

- Stable surface finish without frequent parameter re-tuning

- Lower heat and less smearing to reduce micro-cracks and thermal distortion risks

In multi-axis automatic grinding—especially where contact conditions change along a complex profile—tooling that “forgives” small variations in contact pressure is valuable. Vacuum brazed diamond wheels are often selected because they keep cutting rather than transitioning into rubbing as quickly, improving both throughput and process stability.

4) UDW Series Design Logic: Size Coverage, Compatibility, and Optimization

The UDW series is built around a simple industrial logic: automated grinding needs standard compatibility, but also needs small, application-specific optimizations that protect accuracy and reduce downtime. For buyers, the fastest path to ROI is often not “the most aggressive wheel,” but the wheel that matches the machine’s spindle power, coolant delivery, contact length, and tolerance targets.

Spec planning checklist (useful for RFQ and quick selection)

Wheel geometry

Outer diameter, width, bore, and profile type (straight, cup, profiled).

Diamond grit & concentration

Grit size aligned to stock removal and finish; balance sharpness vs longevity.

Bond & brazing layer

Brazing alloy choice and layer design tuned to heat and cutting force.

Machine & coolant

Spindle power, RPM range, coolant type/flow, and automation duty cycle.

For buyers running multiple SKUs or frequent changeovers, covering a practical size range is essential. The UDW series supports flexible matching across different fixtures and automated stations, while still allowing custom configurations when a specific cast iron grade, contact footprint, or machine path requires tighter optimization.

5) Quality Control, Inspection, and Why It Matters to Overseas Buyers

In global B2B procurement, the real cost of a grinding wheel is measured in process risk. Buyers often prioritize suppliers who can demonstrate repeatability through certification, inspection routines, and traceable quality control—especially when the wheel is used in automated equipment where a single failure can stop an entire line.

What a robust QC package typically includes

- Incoming inspection for wheel bodies and diamond grit consistency

- Brazing process control with repeatable temperature curves and vacuum parameters

- Runout control and balance checks to protect automated spindle systems

- Visual and dimensional inspection with documented tolerances

- Batch traceability for long-term supply stability

For OEMs and contract manufacturers, these controls translate into fewer parameter corrections, fewer “mystery” quality deviations, and faster onboarding for new part numbers.

6) A More Sustainable Grinding Strategy: Efficiency First, Waste Less

Sustainability in metalworking is rarely about slogans; it is about reducing wasted energy, extending tool intervals, and keeping processes stable so parts don’t get scrapped. Vacuum brazed diamond grinding wheels support this shift by maintaining cutting efficiency longer, which can reduce unnecessary heat generation and lower energy consumption per part.

For manufacturers with automated grinding lines, even small percentage gains compound. A 15% improvement in cycle time or a 40% extension in wheel change interval can translate into meaningful yearly capacity gains—without adding new machines.

Suggested infographic ideas (highly shareable on product pages)

- Before/After bar chart: MRR, wheel life, energy per part (vacuum brazed vs electroplated)

- Downtime timeline: planned wheel changes across a 2-week production schedule

- Process window map: stable feed/speed range visualization for automated grinding

FAQ: What Buyers Ask Before Switching to Vacuum Brazed Diamond Wheels

Common questions from OEMs, job shops, and automation integrators

Is a vacuum brazed diamond grinding wheel suitable for cast iron?

Yes. In many cast iron grinding scenarios, vacuum brazed wheels are chosen for stable cutting action and stronger grit retention, particularly when automated grinding runs require consistent force and predictable tool-change intervals.

What kind of life improvement can be expected vs electroplated wheels?

In comparable production settings, many users report roughly 30–80% longer effective life, depending on contact conditions, coolant delivery, and whether the process is heavy stock removal or finish grinding. A quick trial on your machine is the best way to confirm the real number.

Do vacuum brazed wheels require dressing?

Many vacuum brazed diamond wheels are used without conventional dressing routines, but process optimization may still include cleaning, conditioning, or parameter tuning to match the part geometry and finish requirements.

Can the UDW series be customized for automated equipment?

Yes. Typical customization includes wheel diameter and width, bore size, profile shape, diamond grit, and brazing layer design—so the wheel matches spindle power, robotic path strategy, and tolerance targets.

What information should be provided for an accurate recommendation?

Sharing workpiece material/grade, target surface finish, stock removal per pass, machine model (or spindle power/RPM), coolant type, and current wheel specification usually enables a fast, actionable proposal for an automated grinding solution.

Experience the Difference in Automated Grinding

If your line is ready to move beyond electroplated wheels, the UDW Series vacuum brazed diamond grinding wheel can be configured for cast iron and other demanding metalworking tasks—built for stable performance in multi-axis automation and long production runs.