Vacuum Brazing Explained: A Practical Way to Raise Wear Resistance and Metalworking Quality

In modern metalworking, the gap between “acceptable” and “high-performing” often comes down to surface integrity, tool life, and repeatability. Vacuum brazing has quietly become one of the most effective routes to achieve all three—especially in the manufacturing of high-performance diamond grinding wheels used for aggressive cutting and precision finishing.

What Vacuum Brazing Really Does (and Why Shops Care)

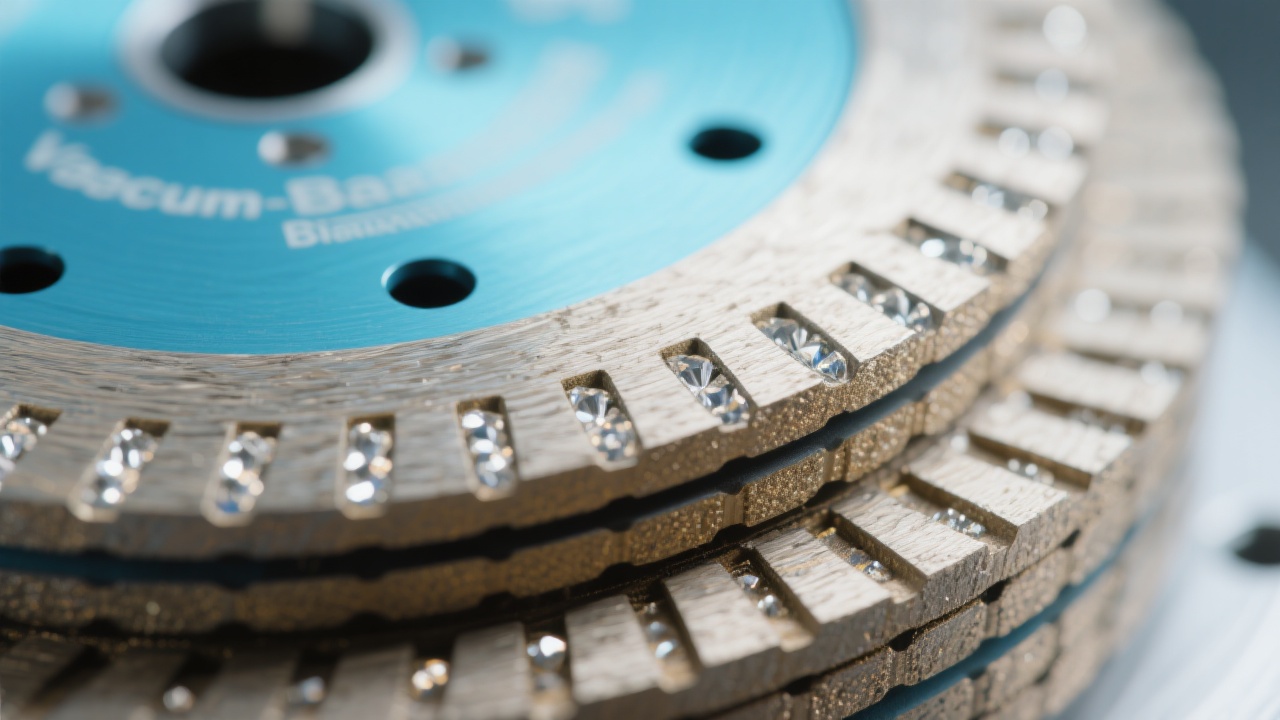

Vacuum brazing is a joining process where a filler alloy melts and wets the base material inside a controlled vacuum chamber. By removing oxygen and other reactive gases, the process minimizes oxidation and enables cleaner, stronger metallurgical bonding. For grinding tools—especially vacuum brazed diamond wheels—this matters because grain retention directly impacts cutting efficiency and wear behavior.

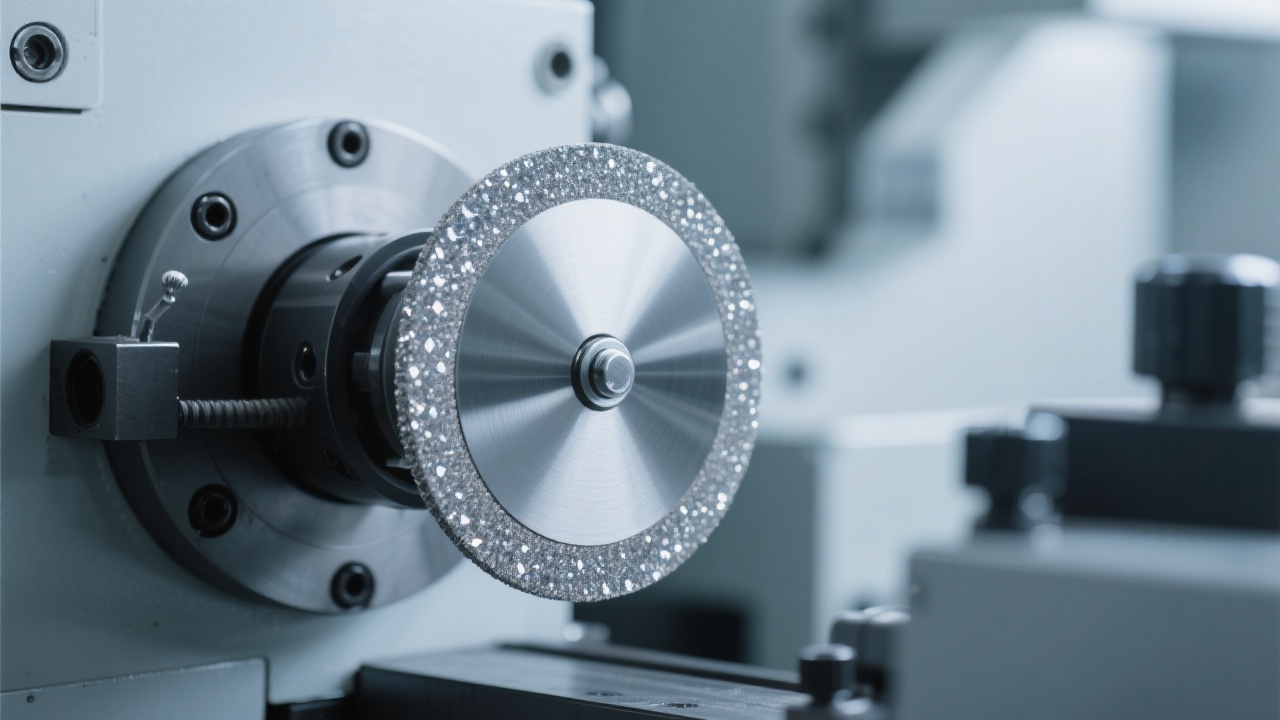

In many industrial settings, vacuum levels typically reach around 10⁻³ to 10⁻⁵ mbar, while brazing temperatures commonly sit in the 800–1100°C range (depending on alloy and substrate). The practical benefit is straightforward: a more uniform bond layer, less contamination, and a cutting edge that stays sharper longer.

Wear Resistance: The Hidden KPI Behind Higher Throughput

When buyers ask for “wear resistance,” they are usually asking for a predictable cost per part. In grinding and deburring operations, tool wear is rarely linear—once grains start shedding, heat rises, the wheel glazes, and surface finish becomes inconsistent. Vacuum brazing reduces that cascade by improving grain anchoring strength and maintaining a more open cutting structure.

In practical shop trials reported across metalworking applications, vacuum brazed diamond tools often deliver 2× to 5× service life compared with conventional resin-bond solutions in heavy-load grinding, while also reducing unplanned wheel changes. Even modest gains—say 20–35% fewer changeovers—can translate into measurable OEE improvement on a busy line.

Quality Upgrades You Can Measure: Heat, Burrs, and Surface Integrity

Metal processing quality is not just about Ra values—it is also about thermal damage, micro-cracks, burr formation, and dimensional stability. Vacuum brazed diamond wheels tend to cut “freer” because more diamond is exposed and better supported. That reduces rubbing, which in turn reduces heat.

In operations like tungsten carbide edge preparation, hardfacing cleanup, and cast iron defect removal, a cooler cutting action can reduce the risk of localized tempering and rework. Many shops report cycle time reductions of roughly 10–25% when switching from lower-retention bonds to vacuum brazed structures—especially where aggressive stock removal previously forced multiple passes.

Quick Comparison (Typical Industrial Outcomes)

Note: Ranges vary by workpiece material, wheel geometry, coolant strategy, and machine rigidity. These figures are provided as practical reference points for industrial evaluation.

Cleaner and More Efficient: Why Vacuum Brazing Aligns with Modern Compliance

Environmental pressure is now part of supplier qualification. Vacuum brazing supports cleaner production by limiting oxidation and reducing the need for aggressive fluxes common in some conventional brazing approaches. In many plants, this means less post-process cleaning and fewer consumables associated with residue removal.

Efficiency gains show up in two places: reduced scrap from inconsistent finishes and reduced downtime from wheel dressing or frequent replacement. For teams managing high-mix production, “less adjustment, more stable grinding” is often the most valuable performance upgrade.

Application Snapshot: High-Performance Diamond Grinding Wheels in Real Metalworking

Vacuum brazed diamond grinding wheels are widely used when traditional wheels struggle—hard materials, interrupted cuts, and demanding surface requirements. Typical workpiece categories include tungsten carbide, ceramics, hardened steels, cast iron, and composites.

A practical example comes from heavy deburring and weld-seam cleanup. When burrs are stubborn, operators often push pressure higher, which can lead to rapid abrasive loss and unstable finish. With vacuum brazed diamond wheels, the bond strength improves grain retention, enabling a more controlled cut at the same or lower pressure—often improving finish consistency while reducing operator fatigue.

Why Henan Youde Superhard Tools Co., Ltd. Is Focused on Vacuum Brazed Diamond Wheels

Henan Youde Superhard Tools Co., Ltd. develops advanced vacuum brazed diamond grinding wheels designed to convert the benefits of vacuum brazing into daily production value. The design philosophy is simple: maximize cutting effectiveness while maintaining stability—so the wheel behaves predictably across batches and shifts.

Depending on the use case, optimized structures may include controlled diamond exposure, engineered chip space for better swarf evacuation, and wheel geometries tuned for edge work, surface grinding, or profile applications. For buyers, that translates to easier process tuning and faster time-to-stable parameters.

Specification Options That Fit Real Production

Vacuum brazed diamond wheels can be configured for different machine types and finishing targets. Common industrial specification variables include:

- Outer diameter & width: sized for hand tools, bench grinders, CNC grinding, or robotic cells

- Diamond grit range: coarser for fast stock removal, finer for smoother surface requirements

- Wheel profile: flat, cup, dish, or customized forms for edges and complex geometries

- Substrate & brazing alloy system: tuned to thermal behavior, strength, and application load

Process Upgrade Roadmap: Turning Vacuum Brazing into an Advantage

For a metalworking plant, the competitive edge is not the tool alone—it is the stability of the process. Vacuum brazing helps create a grinding wheel that keeps its cutting behavior longer, which supports tighter control of dimensional tolerances and surface outcomes. In a market where delivery dates and defect rates are audited, that stability is a commercial advantage.

Many engineering teams adopt a simple evaluation cycle: choose one bottleneck operation, benchmark baseline KPIs (cycle time, wheel changes, scrap), then run a controlled trial. When the wheel maintains cut rate and reduces the need for operator “compensation,” the savings show up quickly—often as fewer interruptions rather than dramatic line-by-line cost reductions.

Ready to Upgrade Your Grinding Performance?

If your current wheels struggle with fast wear, glazing, or inconsistent finish, it may be time to evaluate a higher-retention solution. Send your workpiece material, target finish, and machine details to get a matched recommendation for a vacuum brazed diamond grinding wheel that fits your process—not a generic catalog pick.

In the next few years, the winners in metal processing won’t just be those with faster machines—they’ll be the teams who can keep quality stable across tougher materials, tighter tolerances, and shorter delivery windows.

.png?x-oss-process=image/resize,h_1000,m_lfit/format,webp)