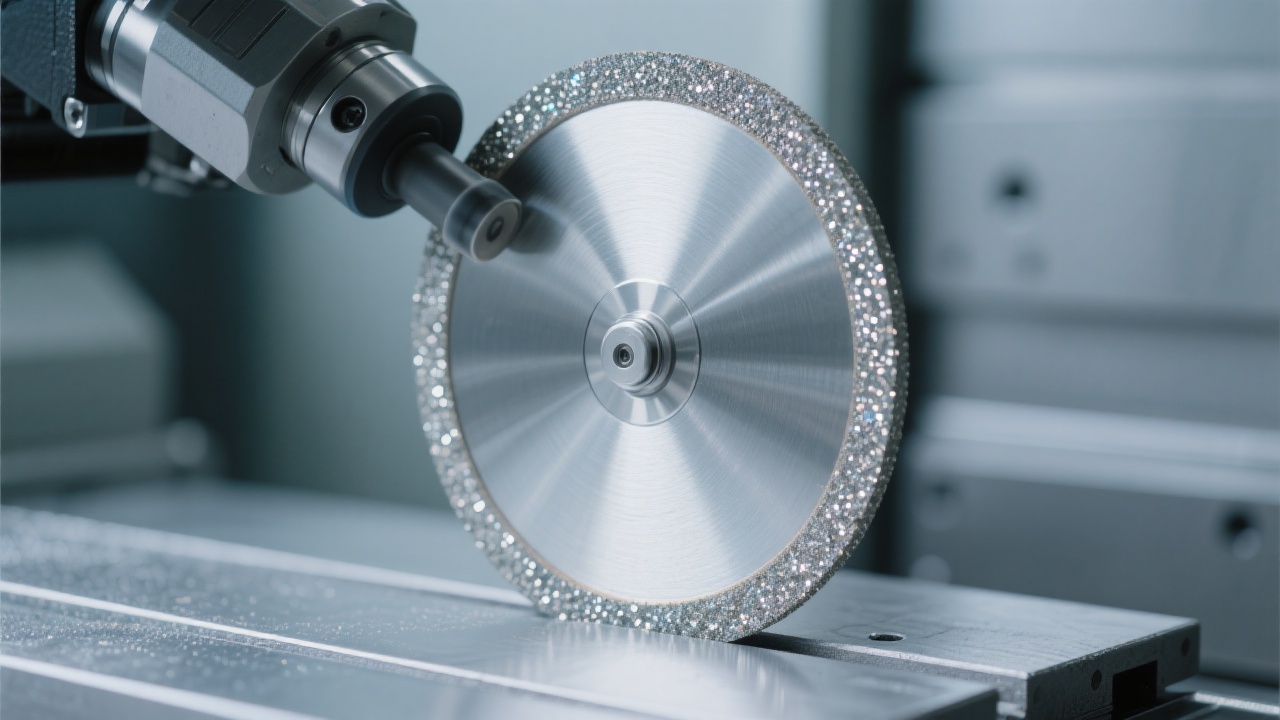

In the evolving landscape of metalworking, manufacturers constantly seek technologies that enhance precision while optimizing production efficiency. Vacuum brazed diamond wheels have emerged as a game-changing solution, particularly when integrated with multi-axis automated grinding equipment. This advanced tooling technology delivers remarkable performance improvements, with industry data showing up to 40% higher material removal rates compared to conventional abrasive solutions, coupled with 300-400% longer service life in precision grinding applications.

Unlike traditional electroplated or resin-bonded wheels, vacuum brazed diamond wheels feature a unique manufacturing process where diamond grains are metallurgically bonded to the substrate in a high-vacuum environment. This creates an exceptional bond strength that allows for deeper diamond grit exposure—typically 70-80% of the diamond particle height compared to just 20-30% in conventional wheels.

The result is a grinding tool that maintains consistent cutting efficiency throughout its lifespan while minimizing heat generation. This technological advantage translates directly to improved workpiece quality, with surface finish improvements of 30-50% reported in铸铁 (cast iron) applications, a material notoriously challenging for precision grinding.

When deployed in multi-axis automated grinding systems, vacuum brazed diamond wheels unlock several performance benefits:

Vacuum brazed diamond wheels are available in a comprehensive range of sizes to accommodate diverse industrial requirements:

The manufacturing process of vacuum brazed diamond wheels involves rigorous quality control measures at every stage. Advanced laser measurement systems ensure dimensional accuracy within ±0.01mm, while ultrasonic testing verifies bond integrity across the entire wheel surface.

Recent innovations include the development of gradient brazing technology, which optimizes diamond distribution based on anticipated wear patterns. This intelligent design further extends wheel life by up to 25% in asymmetric grinding applications, such as complex contour machining in automotive component production.

In today's environmentally conscious manufacturing landscape, vacuum brazed diamond wheels contribute significantly to sustainable production practices. By extending tool life and reducing changeover frequency, these wheels minimize waste generation by approximately 75% compared to conventional abrasive products.

Additionally, the reduced energy consumption associated with lower grinding resistance aligns with global sustainability initiatives. A recent case study in automotive transmission manufacturing demonstrated a 19% reduction in carbon footprint after implementing vacuum brazed diamond technology, while simultaneously increasing production output by 22%.

A leading manufacturer of hydraulic components recently transitioned to vacuum brazed diamond wheels for grinding cast iron valve bodies. The results were striking: production throughput increased by 35%, while tooling costs decreased by 60% due to extended wheel life. Most importantly, the improved surface finish eliminated a secondary polishing operation, reducing overall production time by 28%.

In another application, a heavy machinery manufacturer implemented vacuum brazed wheels for grinding large gear housings. The ability to maintain consistent dimensional accuracy throughout the wheel's lifespan reduced scrap rates from 8% to less than 1.5%, delivering annual savings exceeding $120,000 in material and rework costs.

Discover how vacuum brazed diamond wheels can elevate your automated grinding processes, delivering unprecedented efficiency, precision, and cost savings.

Consult Our Grinding Specialists Today