In the era of Industry 4.0, the metal processing industry is undergoing a profound transformation. Automation and intelligence have become the mainstream trends, which put forward new and higher requirements for the performance of grinding tools. Traditional grinding tools can no longer meet the needs of high - efficiency, high - precision, and green production in modern metal processing.

Automated grinding requires tools with excellent wear resistance, long service life, and stable performance to ensure continuous and efficient operation of the production line. At the same time, in order to adapt to high - speed and high - precision processing requirements, the thermal conductivity and sharpness of tools are also crucial.

Vacuum brazing technology is a revolutionary innovation in the manufacturing of diamond grinding wheels. Compared with the traditional electroplating process, it has significant advantages in many aspects.

In terms of service life, vacuum - brazed diamond grinding wheels can achieve a service life improvement of up to 300% compared with electroplated wheels. This is because the vacuum brazing process firmly bonds the diamond particles to the substrate, reducing the shedding of diamond particles during the grinding process. In addition, vacuum - brazed wheels have better stability. They can maintain stable performance under high - speed and high - load conditions, ensuring the consistency of grinding quality.

Another important advantage is the high thermal conductivity. During the grinding process, a large amount of heat is generated. The high thermal conductivity of vacuum - brazed wheels can quickly dissipate heat, reducing the thermal damage to the workpiece and the grinding wheel itself, and improving the surface quality of the workpiece.

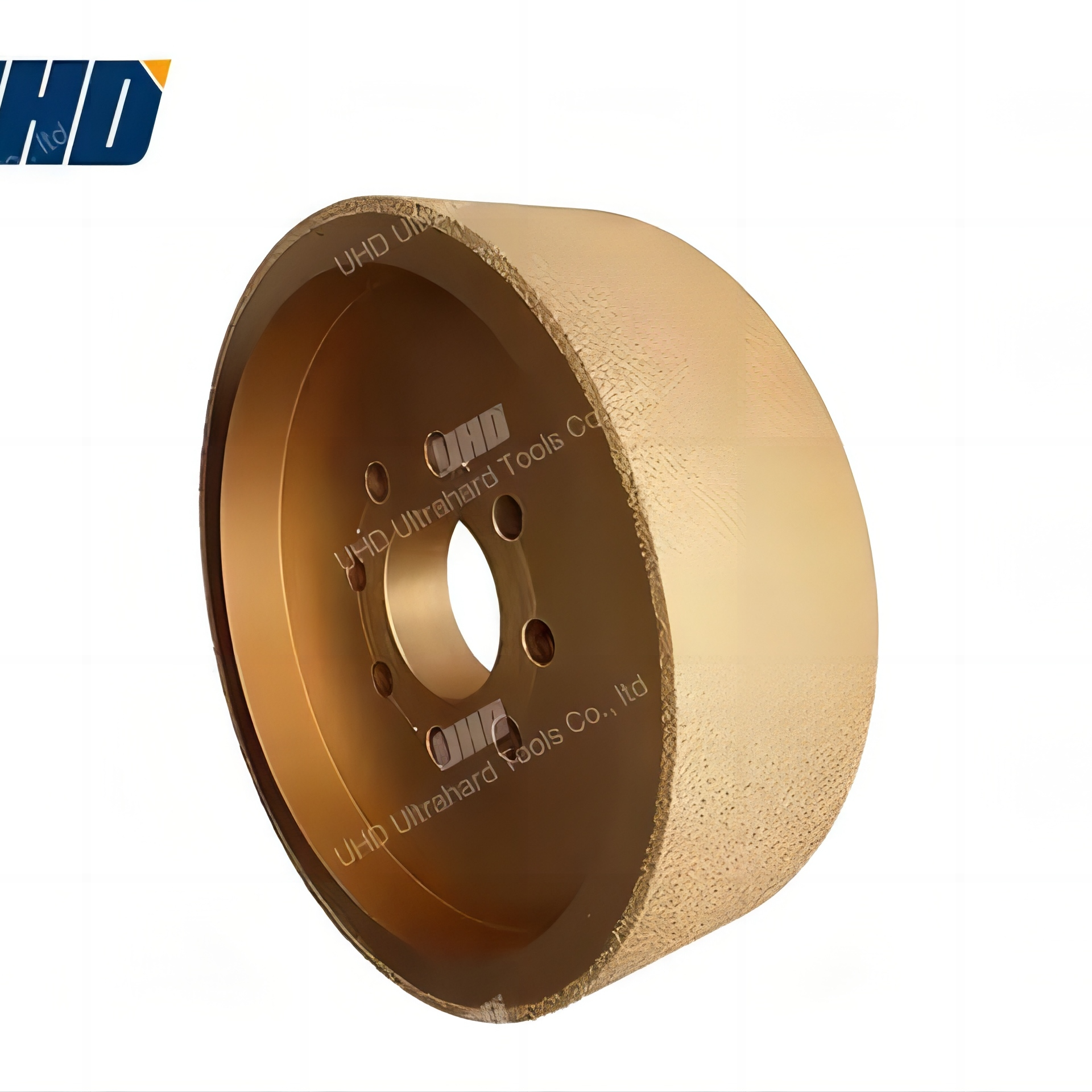

Henan UHD Superhard Tools Co., Ltd. (UHD) has developed a series of high - performance diamond grinding wheels for multi - axis automatic grinding equipment, such as the UDW series. Take a typical model of the UDW series as an example. Its size design is carefully matched with high - speed application scenarios.

The specific size parameters are designed according to the characteristics of high - speed grinding, such as the outer diameter, thickness, and inner hole size, which can ensure the stability and efficiency of the grinding wheel during high - speed rotation. For example, a certain model of the UDW series has an outer diameter of 300mm, a thickness of 20mm, and an inner hole diameter of 75mm, which is very suitable for high - speed multi - axis automatic grinding equipment.

Let's look at some real - world customer cases. A manufacturing company used UHD's UDW series vacuum - brazed diamond grinding wheels in its multi - axis automatic grinding production line. After using these wheels, the grinding efficiency was increased by 40%. The original grinding process took 10 minutes per workpiece, but now it only takes 6 minutes.

In addition, the frequency of tool replacement was reduced by 60%. The traditional electroplated grinding wheels needed to be replaced every 50 workpieces, while the UDW series wheels only needed to be replaced every 125 workpieces. The surface finish of the workpiece was also significantly improved, reaching a Ra value of 0.2μm, which is much better than the Ra value of 0.5μm achieved by the traditional electroplated wheels.

In addition to performance advantages, UHD's vacuum - brazed diamond grinding wheels also have significant environmental compliance and sustainable value. The long service life of these wheels means less waste generation. Compared with traditional electroplated wheels, the amount of waste generated during the production and use process is reduced by 50%.

At the same time, the high - efficiency grinding process reduces energy consumption, which is in line with the requirements of green production in the era of Industry 4.0. This not only helps manufacturing enterprises reduce production costs but also contributes to environmental protection.

UHD understands that different customers have different processing requirements. Therefore, the company provides customized services for complex processing scenarios. Whether it is a special size, a specific shape, or a unique performance requirement, UHD can provide corresponding solutions.

In addition, UHD has a professional technical support team. They can provide comprehensive technical support from product selection, installation, and commissioning to after - sales maintenance, ensuring that customers can use UHD's products with confidence.

In conclusion, UHD's vacuum - brazed diamond grinding wheels, represented by the UDW series, are the ideal choice for intelligent production lines in the era of Industry 4.0. They can help manufacturing enterprises achieve cost reduction, efficiency improvement, and green production. Discover how UHD's diamond grinding wheels can transform your metal processing operations!