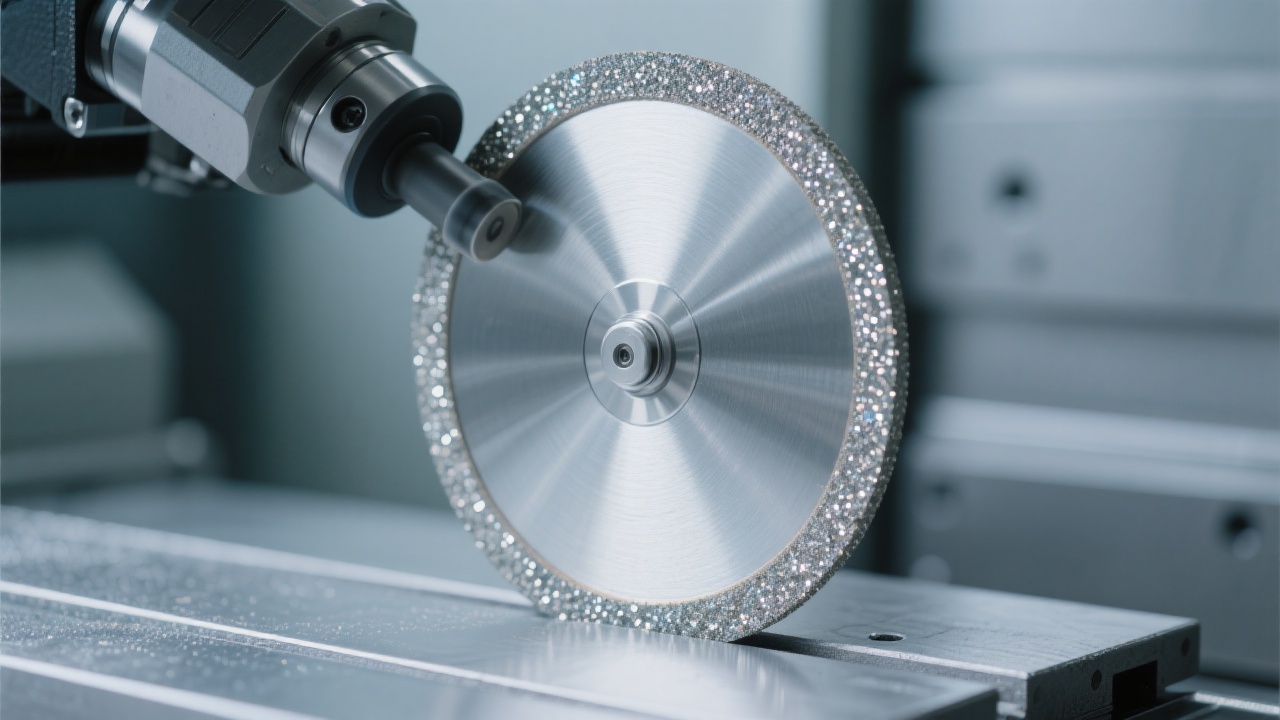

More usable diamond protrusion

Higher protrusion means more aggressive cutting at the same force—helping you raise feed rates while keeping burn risk under control.

If you run multi-axis automated grinding, you already know the real bottleneck is rarely “machine capability”—it’s tool stability: wheel wear, thermal drift, inconsistent finish, and unpredictable downtime. That’s exactly why vacuum brazed diamond grinding wheels are moving from “nice-to-have” to a production standard in many metalworking lines.

The promise is simple and measurable: higher MRR, longer tool life, and more predictable cycle times—without babysitting the process.

“Experience an efficiency leap—starting with the right wheel.” “Make every grind easier, longer-lasting.”

Vacuum brazing bonds diamond abrasives to a metal body using a brazing alloy in a controlled vacuum environment. In practical terms, this creates strong mechanical retention and exposes more usable diamond cutting edges. Compared with conventional electroplated wheels, you typically get:

Higher protrusion means more aggressive cutting at the same force—helping you raise feed rates while keeping burn risk under control.

The braze layer holds grits more securely, which supports longer stable runs and reduces “sudden wheel drop-off” that disrupts automation.

Better heat tolerance in the bonding interface helps maintain cutting consistency—especially valuable when you push higher MRR on cast iron.

In automated grinding, your “tooling choice” is really a production KPI decision. Electroplated diamond wheels can work, but their common limits—grit shedding, glazing behavior, and shorter stable cutting windows—often show up as downtime, finish drift, or conservative feeds.

Note: Ranges depend on material (e.g., gray iron vs. ductile iron), wheel diameter, coolant strategy, and machine rigidity. Use them as starting benchmarks when building your internal business case.

If you want automation-friendly grinding, selection must be based on peripheral speed stability and how your process loads the wheel (contact length, force, and thermal input). The UDW series is commonly specified by diameter. As a practical reference, the larger the diameter, the wider your stable high-speed window and the more forgiving the process becomes for sustained runs.

Safety reminder: Always follow machine and wheel manufacturer limits for maximum RPM and operating speed. Your final speed should be validated by trial cuts and thermal inspection.

Practical tip for engineers: if your line’s top pain is finish drift or unplanned wheel swaps, prioritize a size that supports longer stable runs and better heat control. If the pain is cell compactness and robot reach, prioritize a size that maintains rigidity and clearance without forcing too high RPM.

You don’t select a vacuum brazed diamond wheel by “diamond is harder”—you select it because your process needs repeatable cutting. Use this decision path to reduce trial-and-error:

Gray cast iron often grinds efficiently but generates fine debris—consistent grit exposure helps keep cutting sharp. Ductile iron can increase loading and heat; a more robust wheel body and stable speed window typically improves consistency. If you process multiple grades, prioritize stability over maximum aggressiveness.

If you’re holding tight geometry and surface targets, your goal is not just Ra—it’s repeatability across the full wheel life. Vacuum brazed wheels often help maintain stable cutting behavior longer, which can reduce in-process compensation. Many users report 20–40% fewer finish-related adjustments in automated cells once parameters are stabilized.

If takt time is tight, you’re often tempted to raise feed and speed until burns appear. A vacuum brazed diamond wheel can widen your safe operating zone, enabling ~10–25% takt improvement in real-world lines—mainly by enabling higher MRR and reducing wheel-change downtime. In many plants, the biggest gain is not faster grinding; it’s fewer interruptions.

In automated grinding, you’re not buying a consumable—you’re buying process capability. That’s why a supplier’s quality system and customization capacity directly influence your OEE.

If you’re scaling production, ask for a clear validation path: sample trial → parameter recommendation → pilot run → standardization. That’s how you turn “a better wheel” into a controlled, repeatable process.

You can shorten your selection cycle by starting with a proven sizing and speed reference. Click below to request the UDW Series Vacuum Brazed Diamond Grinding Wheel Selection Handbook (PDF)—including recommended speed windows, typical cast iron applications, and an easy comparison table for UDW455 / UDW405 / UDW355 / UDW305 / UDW255.

Request the UDW Series Vacuum Brazed Diamond Grinding Wheel PDF Selection HandbookTip: share your material grade, target finish, and takt time—so you get a wheel recommendation that’s aligned with your automated grinding constraints.

If your goal is predictable automation, don’t settle for “it works on day one.” Build toward a wheel choice that stays stable across the full run. “Experience an efficiency leap—starting with the right wheel.” “Make every grind easier, longer-lasting.”

Want a quick sanity check before you test? Click to get the handbook, then match your line to the closest scenario and start from a controlled baseline rather than guessing.