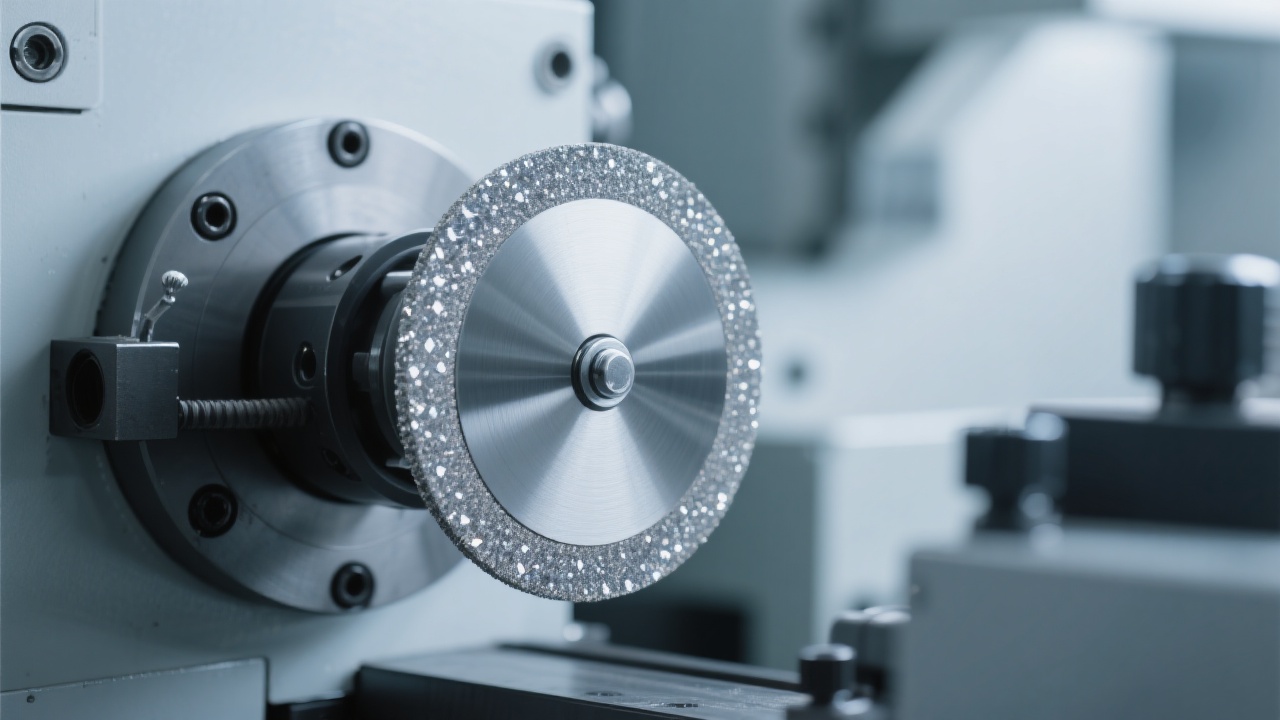

In the fast-paced world of precision manufacturing, where every second and every micron counts, the choice of grinding tools directly impacts production efficiency, product quality, and ultimately, business profitability. Among the innovations reshaping automated grinding processes, vacuum brazed diamond wheels stand out as a transformative technology that delivers unprecedented performance gains. Henan Youde Superhard Tools has emerged as a leader in this field, engineering high-performance diamond wheels specifically designed for multi-axis automated grinding equipment. Let's explore how this technology is redefining industry standards.

Industry Insight: "Manufacturing facilities worldwide are reporting productivity increases of 25-40% after switching to vacuum brazed diamond wheels for their automated grinding operations," notes Martin Schmidt, Senior Manufacturing Engineer at a leading automotive components supplier. "The combination of extended tool life and consistent performance is game-changing."

Vacuum brazed diamond wheels from Henan Youde deliver three fundamental advantages that address the most pressing challenges in automated grinding environments:

Traditional electroplated diamond wheels have long been industry standard, but they come with inherent limitations that vacuum brazing technology has overcome. The key difference lies in the bonding mechanism and resulting wheel structure:

| Performance Metric | Vacuum Brazed Diamond Wheels | Traditional Electroplated Wheels |

|---|---|---|

| Grit Retention Strength | Metallurgical bond (high strength) | Mechanical adhesion (limited strength) |

| Grit Exposure | Up to 70% of grit height exposed | Typically 30-40% exposure |

| Thermal Conductivity | Excellent heat dissipation | Limited heat transfer capability |

| Form Retention | Superior dimensional stability | Prone to rapid wear and shape degradation |

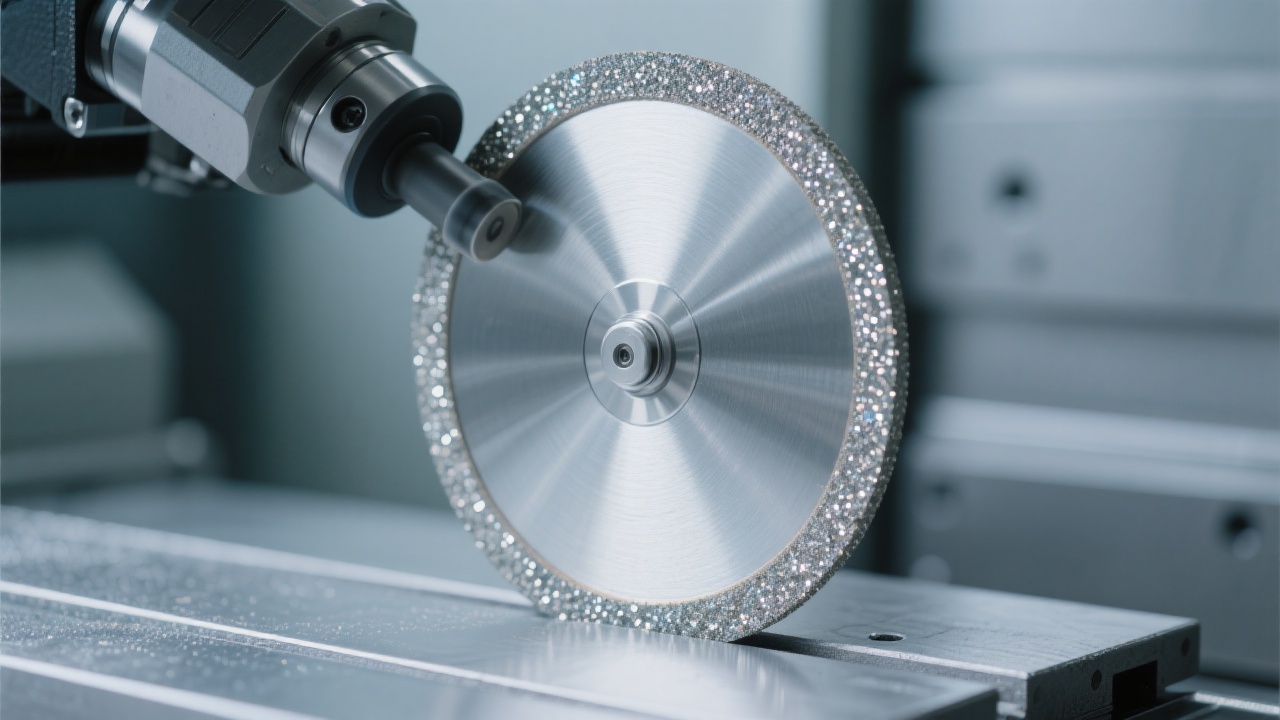

The structural stability of vacuum brazed wheels ensures consistent performance throughout their lifespan, while superior thermal conductivity reduces heat-induced damage to both the wheel and the workpiece—critical factors in maintaining tight tolerances in automated grinding processes.

Henan Youde's UDW series demonstrates a thoughtful approach to matching wheel specifications with application requirements. Each model in the series addresses specific grinding challenges:

Ideal for heavy-duty grinding applications requiring maximum stock removal. The 455mm diameter provides excellent stability at high rotational speeds, making it perfect for large cast iron components.

A versatile mid-sized option that balances material removal rate with precision. Popular in automotive parts manufacturing for transmission components and engine blocks.

Tailored solutions for specialized automated grinding systems, with diameters ranging from 150mm to 600mm to match specific machine requirements.

Cast iron presents unique grinding challenges due to its abrasive nature and varying hardness. Henan Youde's vacuum brazed diamond wheels excel in this demanding application through:

Customer Success Story: "After implementing Youde's vacuum brazed wheels on our automated grinding line for cast iron brake discs, we've reduced cycle time by 28% while improving dimensional consistency by 15%," reports Zhang Wei, Production Manager at a major automotive supplier. "The wheels maintain their precision even after processing over 5,000 parts, a significant improvement over our previous solution."

What truly distinguishes Henan Youde in the market is their commitment to application-specific solutions. Their engineering team works closely with customers to develop custom wheel geometries that optimize performance for specific:

Custom edge geometries for complex part features

Tailored abrasive mixes for specific material challenges

Optimized hub designs for specific machine interfaces

Complementing their product customization is a comprehensive technical support package that includes detailed application guidelines, grinding parameter recommendations, and performance monitoring protocols—ensuring customers achieve optimal results from day one.

Beyond performance advantages, vacuum brazed diamond wheels contribute significantly to sustainable manufacturing practices:

Ready to experience the efficiency, precision, and cost savings of vacuum brazed diamond wheel technology?

Request Your Custom Grinding SolutionOur technical specialists will analyze your specific application and provide a tailored recommendation within 48 hours.

As manufacturing continues to evolve toward greater automation, precision, and sustainability, the tools that power these processes become increasingly critical. Vacuum brazed diamond wheels represent not just an incremental improvement, but a fundamental shift in how grinding operations can contribute to overall manufacturing excellence. By partnering with innovators like Henan Youde, manufacturers gain not just a superior tool, but a competitive advantage that resonates throughout their entire production ecosystem.