As smart manufacturing transforms production floors worldwide, precision machining operations face increasing pressure to deliver higher efficiency, superior quality, and greater consistency. Are you struggling with grinding tools that can't keep pace with your automated production lines? If your current grinding solutions are causing bottlenecks, increasing downtime, or failing to meet tight tolerances, it might be time to explore the technological advancements reshaping the industry.

For decades, electroplated diamond wheels have been the workhorse of metalworking operations. However, in today's smart manufacturing environment, their inherent limitations have become increasingly problematic:

These challenges translate directly to increased operational costs, reduced throughput, and compromised product quality—exactly the opposite of what smart manufacturing aims to achieve.

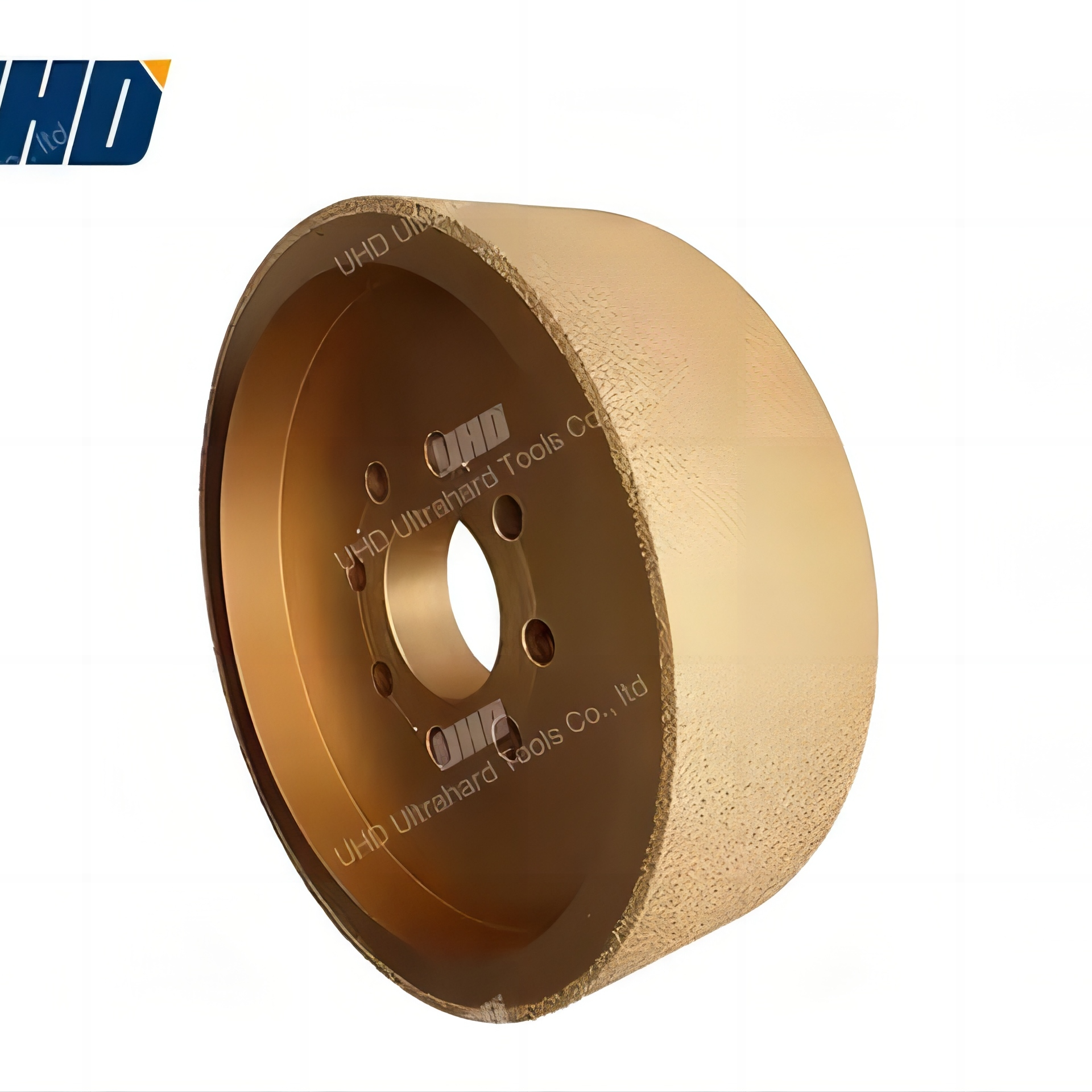

Enter vacuum brazed diamond砂轮 technology—a game-changing innovation that addresses the critical shortcomings of traditional grinding tools. Through a sophisticated manufacturing process that bonds diamond grits to the wheel substrate under vacuum conditions at temperatures exceeding 1000°C, these advanced tools deliver transformative performance benefits:

Vacuum brazed wheels typically last 3-5 times longer than conventional electroplated alternatives, with average lifespans of 80-120 hours in continuous operation. This dramatic extension reduces tool changeovers by up to 70%.

Maintaining consistent tolerances of ±0.002mm throughout their lifespan, these wheels deliver the precision required for aerospace, medical, and high-precision automotive components.

With improved chip evacuation and higher grit exposure, material removal rates increase by 35-45% compared to traditional wheels, significantly boosting production throughput.

Advanced bonding technology minimizes heat transfer to workpieces, reducing thermal damage and improving surface finish quality by up to 40%.

The UDW series of vacuum brazed diamond wheels exemplifies how modern grinding tools are being optimized for the specific demands of automated manufacturing environments. Available in over 20 standard configurations—and with virtually unlimited custom possibilities—these wheels are engineered with smart factories in mind:

Numerous manufacturers have already experienced the transformative benefits of vacuum brazed diamond wheels. A leading automotive component supplier specializing in transmission parts reported:

Similarly, a medical device manufacturer producing orthopedic implants noted significant improvements in surface finish quality and dimensional consistency, enabling them to meet tighter regulatory requirements while increasing production volume by 35%.

The true power of vacuum brazed diamond technology lies not just in the superior performance of the tools themselves, but in the ability to customize solutions to your specific manufacturing challenges. Whether you're working with exotic materials, complex geometries, or unique production constraints, a collaborative approach to tool design can deliver even greater benefits:

Experience the difference vacuum brazed diamond technology can make in your smart manufacturing processes. Discover how these advanced tools can enhance your manufacturing operations, improve product quality, and reduce costs.

Request Your Custom Grinding Solution AssessmentAs smart manufacturing continues to evolve, the tools you choose will play an increasingly critical role in determining your competitive position. The transition from conventional grinding tools to vacuum brazed diamond technology represents more than just an incremental improvement—it's a fundamental shift in your ability to meet the demands of modern manufacturing. What could a 30-50% improvement in grinding efficiency mean for your production goals this year?