In the competitive landscape of modern manufacturing, precision and efficiency are no longer optional—they're essential. As metalworking industries face increasing pressure to deliver higher quality products while reducing environmental impact, vacuum brazing technology has emerged as a game-changing solution. This advanced joining process is redefining standards for tool durability, performance, and sustainability, particularly in the production of diamond grinding tools. Let's explore how this technology works and why it's becoming the preferred choice for forward-thinking manufacturers worldwide.

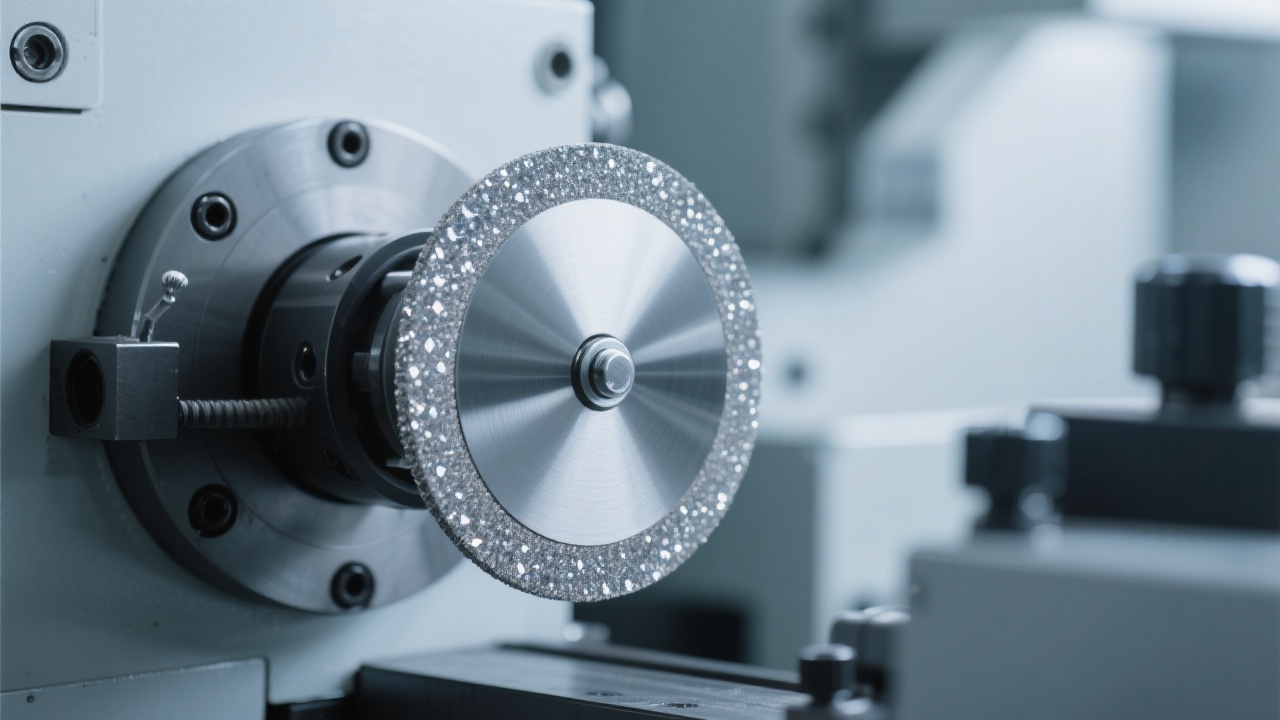

Vacuum brazing represents a significant advancement over traditional bonding methods, utilizing a controlled environment to create metallurgical bonds of exceptional strength. Unlike conventional processes that rely on atmospheric conditions, vacuum brazing eliminates oxygen and contaminants by performing the operation in a sealed, evacuated chamber. This controlled environment allows for precise temperature management—typically between 800°C and 1100°C depending on the alloy—resulting in uniform heat distribution and superior bond integrity.

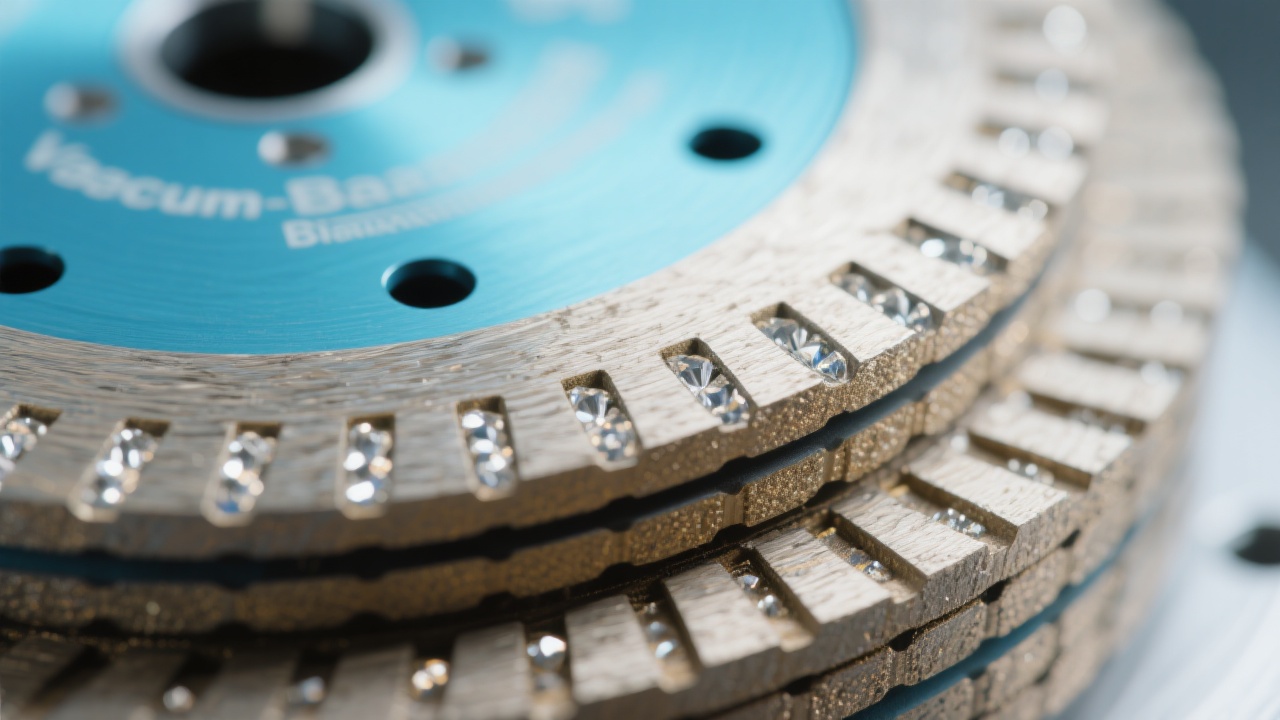

The process begins with carefully selected filler metals that boast lower melting points than the base materials, ensuring the substrate remains unaffected while creating a robust joint. During heating, these fillers flow capillary-like into joint spaces, forming a bond that often exceeds the strength of the original materials. This method not only enhances structural integrity but also preserves the sharpness and cutting efficiency of diamond grains—a critical advantage for grinding applications.

The most compelling advantage of vacuum brazed diamond tools lies in their exceptional wear resistance. Independent testing has shown that vacuum brazed砂轮 tools can achieve up to 300% longer service life compared to conventional electroplated alternatives. This dramatic improvement stems from the unique metallurgical bond that securely anchors diamond grains, preventing premature pull-out during aggressive grinding operations.

In practical terms, this translates to fewer tool changes, reduced downtime, and significant cost savings over time. A case study conducted with automotive manufacturers revealed that switching to vacuum brazed diamond砂轮 tools reduced tool replacement frequency by 67% while maintaining consistent surface finish quality. The secret lies in how the brazing alloy creates a mechanical interlock with the diamond grains, distributing cutting forces more evenly and minimizing stress concentrations.

Beyond performance benefits, vacuum brazing technology offers compelling environmental advantages that align with global sustainability initiatives. Traditional electroplating processes typically generate hazardous waste streams containing heavy metals and toxic chemicals, requiring costly disposal procedures and creating environmental liabilities. In contrast, vacuum brazing operates without harmful chemicals, significantly reducing a manufacturer's environmental footprint.

Energy consumption analysis shows that vacuum brazing systems can reduce energy usage by approximately 25% compared to conventional bonding methods, thanks to improved thermal efficiency and precise process control. Additionally, the extended tool life means fewer tools need to be manufactured and disposed of, reducing overall resource consumption. For companies aiming to achieve ISO 14001 certification or meet strict environmental regulations, these benefits represent both ethical and financial advantages.

Henan Youde Superhard Tools Co., Ltd. has emerged as an industry leader in applying vacuum brazing technology to diamond grinding tools. Their ultra-high precision brazed diamond砂轮 represents the pinnacle of this technology, delivering exceptional results in demanding metalworking applications. Specifically engineered for cast iron processing, these tools combine remarkable durability with superior surface finish capabilities.

One notable application involved a major automotive components manufacturer facing challenges with premature tool wear during cylinder head grinding operations. By switching to Henan Youde's vacuum brazed diamond砂轮, the manufacturer achieved a 52% increase in tool life while improving surface finish consistency by 38%. The production line saw a 22% reduction in downtime related to tool changes, directly contributing to increased overall productivity and reduced per-unit manufacturing costs.

The secret to this performance lies in Henan Youde's proprietary brazing alloy formulation and precision manufacturing process. Each砂轮 undergoes rigorous quality control, with dimensional tolerances maintained within ±0.01mm and diamond grain distribution optimized for consistent cutting performance. This attention to detail ensures that every tool delivers predictable, reliable results even in the most challenging production environments.

While vacuum brazed tools may represent a higher initial investment compared to conventional alternatives, the total cost of ownership tells a different story. A comprehensive cost analysis conducted over a 12-month period revealed that manufacturers using vacuum brazed diamond tools experienced an average savings of 35% compared to those using traditional electroplated tools. This calculation accounts for tool replacement costs, downtime, labor for tool changes, and energy consumption.

For high-volume production facilities, these savings can be substantial. A mid-sized automotive parts manufacturer with five grinding stations reported annual savings of over $85,000 after transitioning to vacuum brazed technology. The improved process stability also reduced scrap rates by an average of 18%, further enhancing the economic benefits.

Experience the durability, efficiency, and sustainability of vacuum brazed diamond tools for yourself.

Discover Henan Youde's Vacuum Brazed SolutionsJoin industry leaders achieving superior results with advanced brazing technology

As manufacturing continues to evolve, the adoption of innovative technologies like vacuum brazing will separate industry leaders from followers. The combination of enhanced tool performance, environmental sustainability, and long-term cost savings makes this technology not just an option but a strategic imperative for companies looking to maintain competitive advantage in an increasingly demanding global market. The future of metalworking belongs to processes that deliver both precision and responsibility—and vacuum brazing is leading this transformation.