As global manufacturing shifts toward cleaner, smarter processes, metalworking shops are increasingly adopting vacuum brazed diamond grinding wheels — especially for cast iron applications. These tools aren’t just a trend; they represent a measurable leap in performance, safety, and sustainability.

For decades, resin-bonded diamond wheels dominated the market — but with serious limitations:

These inefficiencies directly impact productivity and worker health — making them unsustainable in today’s compliance-driven markets like the EU and North America.

By bonding diamonds to a tungsten carbide core using high-temperature vacuum brazing, we eliminate the organic resin matrix that breaks down quickly. The result? A tool that delivers:

| Feature | Traditional Wheel | Vacuum Brazed Wheel |

|---|---|---|

| Sharpness | Standard | 3x sharper edge retention |

| Lifespan | 4–6 hrs | 400+ hrs (100x longer) |

| Dust Emission | High (visible particulates) | Near-zero (no volatile compounds) |

This isn’t just incremental improvement — it’s transformational. One German automotive supplier reported a 70% reduction in wheel changeovers per shift after switching, translating into an additional 3.5 productive hours daily.

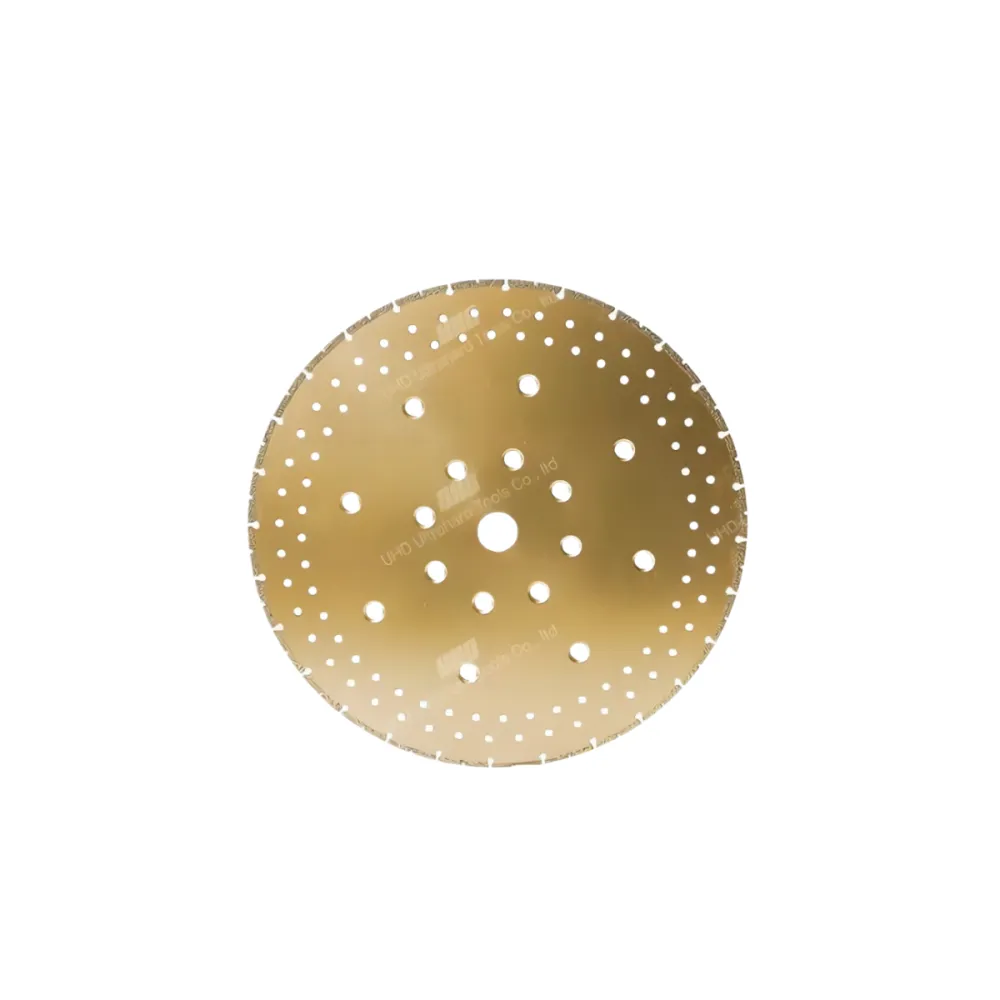

With optimized geometry and balanced mass distribution, these wheels run at speeds up to 60 m/s without vibration — critical for maintaining consistent surface finish on precision castings. The absence of resin means no toxic fumes during operation, improving both air quality and OSHA compliance.

From flat to conical profiles, custom grit sizes, and segmented designs — vacuum brazed wheels can be tailored to your specific application: whether you’re machining brake rotors, engine blocks, or turbine blades.

Manufacturers in the U.S., Japan, and UAE have already adopted this solution — not because it’s trendy, but because it solves real problems: less waste, fewer interruptions, and better results.

Ready to reduce downtime, boost precision, and future-proof your shop?